1. Introduction

1.1. Definition of Leaf Chains

In the world of industrial power transmission, where reliability and sheer strength are paramount, the leaf chain stands as a fundamental yet often overlooked component. Unlike its more common cousin, the roller chain, a leaf chain is characterized by its simple, robust construction of multiple parallel link plates—the “leaves”—pinned together by solid steel pins. This assembly, devoid of rollers or bushings, creates a compact and incredibly strong series of linkages designed to operate in pure tension. The leaf chain’s primary function is not to transmit high-speed rotational power, but to provide a reliable, high-strength pulling or lifting member in demanding applications.

1.2. Overview of Their Role in Industrial Machinery

Leaf chains are the workhorses embedded within the core of many heavy-duty machines. They are engineered to handle strenuous, often slow-moving, applications where the primary requirement is to lift, lower, or pull substantial loads with precision and safety. You won’t typically find them in the drive train of a motorcycle, but you will find them at the heart of a forklift’s lifting mechanism or guiding the massive movements of an industrial crane. Their role is to translate power into controlled linear motion, acting as the critical link between the drive system and the load itself, ensuring stability and predictability under immense stress.

1.3. Importance in Lifting, Conveying, and Power Transmission Applications

The significance of leaf chains becomes most apparent in their core applications. In lifting, they are indispensable for their high tensile strength and minimal elongation under load, making them the chain of choice for forklift masts, overhead cranes, and hoists—applications where failure is not an option. In conveying systems, particularly those handling heavy products like automotive frames or large containers, leaf chains provide the durable, continuous pull needed for smooth operation. Finally, in specialized power transmission scenarios, such as the timed movements in bottling or packaging machinery, their precision and durability ensure synchronized operation and minimize downtime. In essence, leaf chains are unsung heroes, providing the silent, muscular force that drives essential industrial processes, forming a backbone of modern material handling and manufacturing.

2. Historical Development of Leaf Chains

2.1. Origins and Evolution of Chain Technology

The story of the leaf chain is inextricably linked to the millennia-old history of chain technology itself. The earliest chains, dating back to at least 225 BC with the work of the Greek philosopher Philo of Byzantium, were simple, hand-forged links used for lifting water and securing anchors. For centuries, chain design remained relatively unchanged, reliant on blacksmithing techniques. The true catalyst for evolution was the Industrial Revolution of the 18th and 19th centuries. The burgeoning demands of mining, manufacturing, and transportation necessitated stronger, more reliable, and mass-producible chains. This period saw the invention of the welded chain and, most importantly, the patented bush roller chain by Hans Renold in 1880, which introduced the precision engineering principles that would pave the way for specialized chains like the leaf chain.

2.2. Emergence of Leaf Chains in Industrial Use

As machinery became more powerful and complex, the limitations of standard roller chains in certain applications became apparent. Roller chains were excellent for high-speed power transmission but could be susceptible to failure under heavy, static, or shock-loading conditions, especially in linear lifting applications. This performance gap created a need for a chain designed specifically for high-tensile strength and durability without the need for high rotational speeds. The leaf chain emerged as the direct response to this need. Its simple, all-steel plate-and-pin construction, with a larger bearing area, proved far more resistant to the punishing loads found in the lifting mechanisms of early cranes, hoists, and, later, forklifts. It was a classic case of engineering specialization—the right tool for the job.

2.3. Key Milestones in Manufacturing and Design Improvements

The development of the leaf chain was not a single event but a series of incremental advancements driven by material science and manufacturing precision. Key milestones include:

- Heat Treatment: The introduction of controlled heat-treating processes (like hardening and tempering) for both pins and plates significantly increased the surface hardness for wear resistance while maintaining a tough, shock-absorbent core.

- Precision Stamping: Advancements in high-precision stamping technology allowed for the mass production of link plates with consistent, high-quality dimensions and smooth edges, which are critical for reducing stress concentrations and fatigue.

- Precision Grinding and Shot Peening: The development of precision grinding for pins ensured a perfect fit and load distribution, while shot peening—bombarding the components with small media—induces compressive stresses on the metal’s surface, dramatically improving fatigue life by resisting crack propagation.

- Standardization: The establishment of international standards (such as those from ANSI, ISO, and JIS) ensured interoperability, reliability, and safety, allowing engineers to specify leaf chains with confidence for critical applications worldwide.

These innovations transformed the leaf chain from a simple, strong linkage into a highly engineered component whose performance and reliability could be precisely predicted and trusted.

3. Structure and Design

3.1. Basic Components: Plates, Pins, and Links

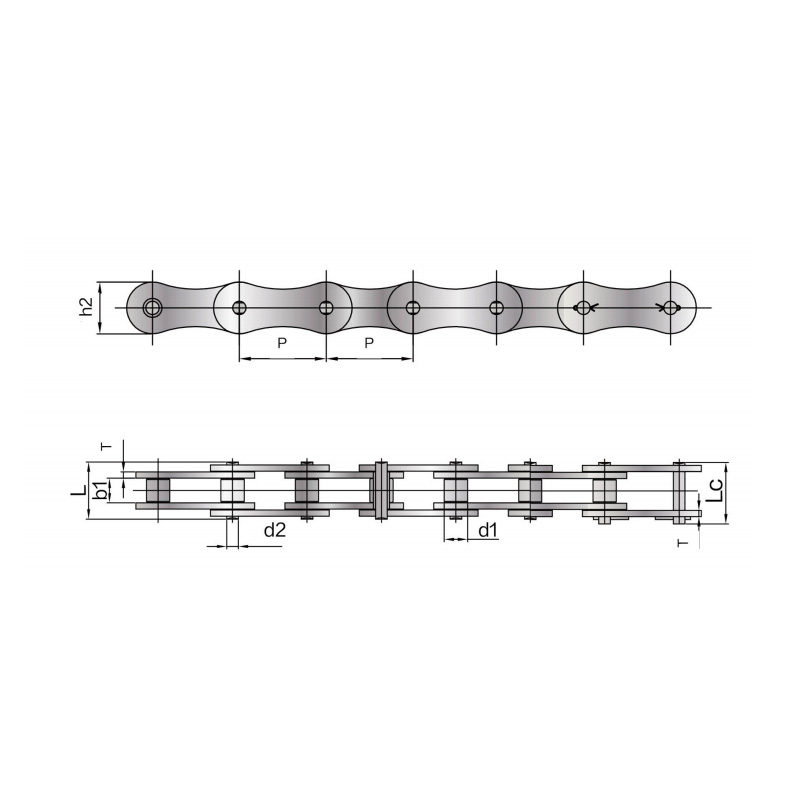

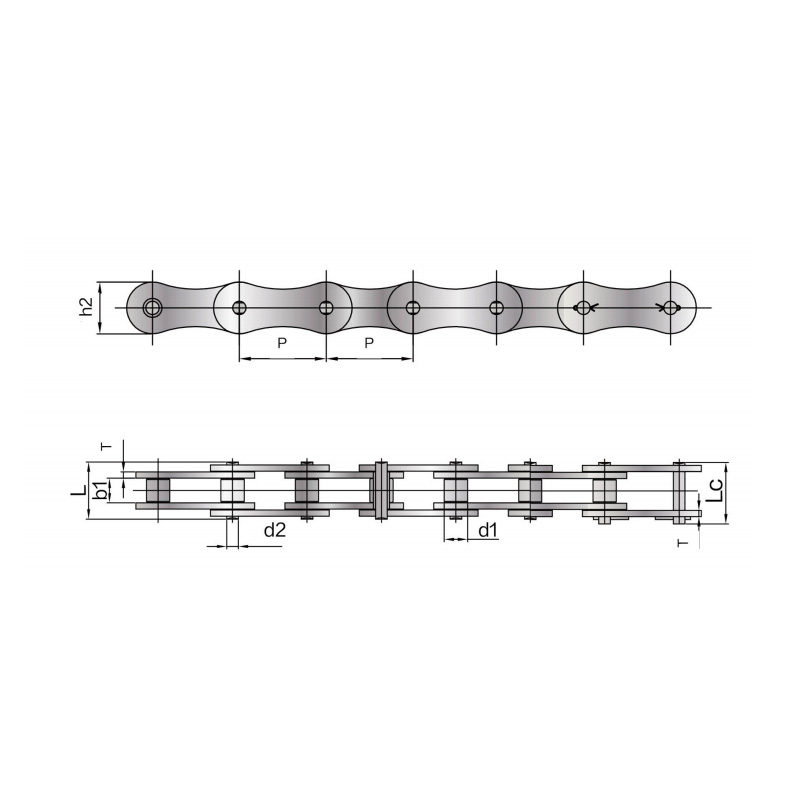

The leaf chain’s reputation for brute strength and reliability stems from its deceptively simple architecture. Unlike more complex chains, it is comprised of just two primary components, meticulously engineered to work in unison:

- Link Plates (Leaves): These are the high-strength steel plates that form the “backbone” of the chain. They are precisely stamped to create a consistent profile with holes drilled for the pins. In a leaf chain, multiple plates are stacked together in parallel on each side, forming the robust “leaf” assembly that gives the chain its name. The number of plates directly correlates to the chain’s tensile strength.

- Pins: These are solid, hardened steel cylinders that serve as the pivoting axles, connecting the interleaved link plates. The pins are press-fit into the holes of the outer set of plates, creating what is known as a “press fit” assembly, while the inner plates pivot freely on them. The precision of the pin’s diameter and its surface finish are critical for minimizing wear and ensuring smooth articulation.

These components assemble into repeating units called links. A “link” in a leaf chain context consists of the pin press-fit into its set of plates, which then connects to the free-floating plates of the adjacent link. This creates a robust, articulated joint capable of handling immense tensile loads with minimal stretch.

3.2. Variations in Design for Different Load Capacities

The fundamental design of leaf chains is not one-size-fits-all; it is strategically varied to meet specific load and application demands. The primary variables are:

- Number of Plate Widths (Leaves): This is the most direct way to scale strength. A single-width chain (e.g., LH series) might have two plates per side, while a double-width chain (e.g., LHH series) stacks four plates per side, effectively doubling the cross-sectional area and thus the load-bearing capacity.

- Plate Thickness and Pin Diameter: For a given chain size, manufacturers may offer heavy-duty versions that feature thicker link plates and larger-diameter pins. This increases the chain’s weight and stiffness but provides a significant boost in working load limits and fatigue resistance.

- Attachment Links: To facilitate connection to machinery, specialized attachment links can be incorporated. These links have extended plates with holes or custom profiles, allowing for easy pinning or bolting to the equipment, which is essential for applications like forklift masts.

These variations are standardized under systems like ANSI (American National Standards Institute) and ISO (International Organization for Standardization), ensuring that a chain designated as, for example, an “AL 82x4” has consistent dimensions and load ratings across different manufacturers.

3.3. Comparison with Roller Chains and Other Chain Types

Understanding what makes a leaf chain unique requires a direct comparison with its closest relative, the roller chain.

| Feature |

Leaf Chain |

Roller Chain |

| Primary Function |

Lifting & Pulling (High-Tension Linear Motion) |

Power Transmission (High-Speed Rotary Motion) |

| Key Construction |

Solid pins, multiple parallel link plates. No rollers. |

Pins, bushings, rollers, and typically single-width link plates. |

| Load Type |

Excellent for static, shock, and high-tensile loads. |

Optimized for dynamic, cyclic loads and torque transmission. |

| Strength/Weight |

Extremely high tensile strength for its size and weight. |

High strength, but designed with a balance for speed and efficiency. |

| Articulation & Speed |

Less smooth articulation; not suitable for high speeds. |

Smooth rolling action over sprockets; ideal for high-speed operation. |

| Elongation |

Designed for minimal permanent elongation. |

Can experience working elongation; requires take-up systems. |

In essence, while a roller chain is built for motion, a leaf chain is built for force. Choosing the wrong type for an application—using a roller chain for heavy lifting, for instance—can lead to rapid wear, premature failure, and serious safety hazards.

4. Applications in Industry

The robust and reliable nature of leaf chains makes them indispensable across a wide spectrum of industrial sectors. Their ability to handle high-tensile loads with precision and safety has cemented their role in everything from warehouse logistics to heavy manufacturing.

4.1. Material Handling Systems

In the vast world of material handling, efficiency and reliability are paramount. Leaf chains are the driving force behind many of the systems that move products through facilities. They are commonly found in:

- Overhead Conveyors: Where they are used to pull trolleys along I-beam tracks, transporting heavy assemblies, such as automotive bodies, through painting and assembly lines.

- Drag Conveyors: In these systems, leaf chains are used to pull flights or paddles through troughs to move bulk materials like grain, cement, or minerals, often in abrasive and demanding environments.

- Vertical Lift Conveyors: Also known as continuous vertical conveyors, these systems use leaf chains to lift and lower products between different floors of a facility, relying on the chain’s high tensile strength and predictable elongation behavior for safe, stable operation.

4.2. Forklifts, Cranes, and Hoisting Machinery

This is the quintessential application for leaf chains and where their value is most visibly demonstrated. In these lifting applications, the chain is a critical safety component.

- Forklifts: The most common application is within the forklift mast. The leaf chain is anchored at the top of the inner mast and connected to the carriage or the hydraulic cylinder. As the cylinder extends, it pulls the chain, which acts through the mast’s pulleys to lift the inner sections and the load. The chain’s compact design and immense strength are perfectly suited for this confined, high-stress environment.

- Cranes & Hoists: From small jib cranes to large overhead bridge cranes, leaf chains are used in the hoisting mechanism to lift and lower the hook assembly. Their minimal elongation under load ensures precise positioning of heavy loads, which is critical for both safety and operational accuracy.

4.3. Specialized Industrial Uses (e.g., bottling lines, packaging equipment)

Beyond heavy lifting and conveying, leaf chains find critical roles in specialized machinery where precision and synchronization are key.

- Bottling and Canning Lines: In high-speed filling and capping machines, leaf chains are often used in timing applications. They ensure that various stations—for cleaning, filling, sealing, and labeling—operate in perfect synchrony. Their durability prevents the costly misalignment that can lead to downtime or product loss.

- Packaging Equipment: Machines that form, fill, and seal boxes often use leaf chains to drive the indexing mechanism that moves packages through different stages. The chain’s strength handles the intermittent start-stop forces, while its precision maintains the registration needed for accurate packaging.

- Forestry and Construction Equipment: In machinery like timber harvesters or excavator attachments, leaf chains are used in powerful grapples and clamps, where they must withstand extreme shock loads and abrasive conditions.

The following table summarizes the core applications and the specific properties of leaf chains that make them the ideal choice:

| Application |

Primary Function |

Why Leaf Chains are Used |

| Forklift Mast |

Lifting the load carriage |

High tensile strength, compact design, and minimal elongation for safety and stability. |

| Overhead Crane |

Hoisting the hook and load |

Precise load control and reliability for critical lifting operations. |

| Drag Conveyor |

Pulling bulk materials |

Durability and resistance to abrasive environments. |

| Bottling Line |

Synchronizing machine stations |

Precision and fatigue resistance for maintaining timing under cyclic loads. |

In summary, wherever there is a need for reliable, high-strength linear motion—whether lifting tons of steel or synchronizing the packaging of consumer goods—the leaf chain is a trusted and often essential component.

5. Performance Characteristics

Understanding the performance characteristics of a leaf chain is crucial for proper selection, safe operation, and predicting its service life. These chains are engineered not for speed, but for unwavering performance under demanding conditions.

5.1. Load Capacity and Fatigue Resistance

The defining performance metric for any leaf chain is its load capacity.

- Ultimate Tensile Strength (UTS): This is the absolute maximum load the chain can withstand in a single pull-to-destruction test. It is a critical safety indicator but should not be used for design purposes.

- Working Load Limit (WLL): This is the maximum load the chain is designed to handle in regular service. It incorporates a significant safety factor (often 4:1 to 8:1 for lifting applications) against the UTS to account for dynamic loads, shock, and potential wear. Selecting a chain with a WLL appropriate for the application is non-negotiable for safety.

- Fatigue Resistance: In applications with cyclic loading (repeated lifting and lowering), the chain is subject to metal fatigue. Fatigue resistance is the chain’s ability to endure these stress cycles without developing cracks. This property is heavily influenced by material quality, the precision of the pin-plate fit, and critical manufacturing processes like shot peening, which enhances the metal’s surface to resist crack initiation.

5.2. Durability and Elongation Behavior

Durability and elongation are interlinked characteristics that directly impact a chain’s usable lifespan.

- Wear and Elongation: The primary wear in a leaf chain occurs at the pivot points between the pins and the link plates. As the chain articulates under load, this friction causes material to wear away, increasing the pitch (the center-to-center distance between pins). The cumulative effect of this wear across all the links is chain elongation.

- Critical Distinction: It is vital to understand that this is wear elongation, not the elastic stretch experienced by a cable or rope. This elongation is permanent and irreversible. Excessive elongation (typically over 2-3% of the original length) indicates significant wear, reduces precision, and increases the risk of the chain jumping off the sprocket, leading to catastrophic failure.

- Durability Factors: A chain’s resistance to wear is determined by the hardness of the pins and plates, the quality of the lubrication, and the alignment of the system. A well-lubricated, properly aligned chain in a clean environment will exhibit far superior durability and slower elongation.

5.3. Maintenance and Lubrication Requirements

Leaf chains are low-maintenance but are not “no-maintenance” components. Proper care is the single greatest factor in maximizing their service life and ensuring safety.

- The Role of Lubrication: Lubrication is not optional; it is essential. Its primary functions are to:

- Reduce Wear: Form a protective film between the pin and plate, minimizing metal-on-metal contact.

- Dissipate Heat: Carry heat away from the critical wear surfaces.

- Prevent Corrosion: Protect the steel components from rust and oxidation.

- Lubrication Regimen: The frequency and type of lubricant depend on the operating environment (temperature, presence of contaminants). In dirty environments, a heavy-grade oil or grease can help seal out debris, while in clean, high-cycle applications, a penetrating oil might be preferred to ensure it reaches the internal bearing surfaces. A regular schedule based on operating hours is highly recommended.

- Inspection and Maintenance: Regular visual inspection for signs of wear, damage, cracks, or corrosion is critical. Chains should be checked for easy articulation, and elongation should be measured periodically. A chain that has reached its wear limit must be replaced immediately—it should never be repaired or modified in the field.

The table below contrasts the performance priorities of leaf chains versus roller chains, highlighting their specialized nature:

| Performance Characteristic |

Leaf Chain Priority |

Roller Chain Priority |

| Load Capacity |

Maximized Static & Shock Load |

Optimized for Dynamic/Torque Load |

| Elongation |

Minimized Wear Elongation (Critical for precision) |

Managed Elastic/Working Elongation |

| Lubrication |

Critical for pin/plate wear life |

Critical for roller/bushing/sprocket life |

| Fatigue Life |

High-cycle, high-tension fatigue resistance |

High-speed, rotational fatigue resistance |

6. Innovations and Modern Trends

While the fundamental principle of the leaf chain remains unchanged, the industry is far from static. Continuous innovation in materials, design, and technology is pushing the boundaries of what these components can achieve, focusing on increased performance, reduced environmental impact, and enhanced operational intelligence.

6.1. Lightweight and High-Strength Materials

The pursuit of higher strength-to-weight ratios is a primary driver of innovation. Heavier chains contribute to a machine’s overall weight, reducing its payload capacity and energy efficiency. Modern advancements include:

- Advanced Alloy Steels: The development of new, clean steel alloys combined with precise heat-treatment processes allows manufacturers to achieve higher tensile strength and wear resistance without increasing the physical dimensions of the plates and pins.

- Case Hardening and Carbonitriding: These are advanced heat-treatment techniques that create an extremely hard, wear-resistant outer case on the components while maintaining a tough, ductile core that can absorb shock loads, significantly enhancing both durability and fatigue life.

- Exploration of Composites and Alternative Materials: While steel remains dominant, research into high-strength, lightweight materials like titanium alloys or advanced composites continues for specialized, high-value applications where weight reduction is critical.

6.2. Noise Reduction and Smooth Operation Improvements

As workplace noise regulations become stricter and user comfort more valued, reducing the operational sound of machinery is a key focus. For leaf chains, noise primarily comes from the impact of plates and the articulation of joints.

- Precision Manufacturing: Tighter tolerances in the pin and plate holes ensure a better fit, minimizing free movement and the resulting “slap” and vibration.

- Optimized Link Plate Profiles: Redesigning the contour of the link plates to facilitate smoother engagement and disengagement with the sprocket teeth can reduce impact forces and noise generation.

- Integrated Polymer Components: The use of engineered polymer or nylon guides and wear strips on the link plates can dampen vibration and reduce metal-on-metal contact noise, especially in applications like linear guides on forklift masts.

6.3. Smart Monitoring and IoT-Enabled Chain Systems

The rise of Industry 4.0 is bringing connectivity and data analytics to even the most fundamental components like leaf chains. The goal is to shift from preventative maintenance (based on time) to predictive maintenance (based on actual condition).

- Embedded Sensors: Researchers and leading manufacturers are developing ways to integrate miniature sensors directly into the chain links. These sensors can monitor critical parameters in real-time, such as load strain, temperature, and elongation.

- Wireless Data Transmission: Using low-power wireless protocols like RFID or Bluetooth, these sensors can transmit data to a central monitoring system. This allows for continuous assessment of the chain’s health without manual inspection.

- Predictive Analytics: The collected data is analyzed by software algorithms that can detect abnormal patterns, such as uneven load distribution or accelerated wear rates. The system can then predict remaining useful life and alert operators to perform maintenance before a failure occurs, dramatically reducing unplanned downtime and improving safety.

The following table summarizes this evolution:

| Aspect |

Traditional Approach |

Modern & Innovative Approach |

| Materials |

Standard Carbon Steel |

Advanced Alloy Steels with Precision Heat Treatment |

| Performance Goal |

High Strength |

High Strength-to-Weight Ratio & Enhanced Fatigue Life |

| Operation |

Acceptable Noise Levels |

Optimized for Noise Reduction & Smooth Articulation |

| Maintenance |

Schedule-Based & Visual Inspection |

IoT-Powered Predictive Maintenance via Sensor Data |

These innovations ensure that the leaf chain, a classic piece of industrial engineering, continues to evolve and remain a vital, efficient, and intelligent component in the modern automated factory.

7. Choosing the Right Leaf Chain

Selecting the correct leaf chain is a critical engineering decision that directly impacts safety, productivity, and total cost of ownership. It requires a careful balance of multiple factors, moving beyond simply matching a chain to a load rating.

7.1. Factors Affecting Selection: Load, Speed, and Environment

A systematic approach to selection involves evaluating the following key parameters:

-

Load Characteristics: This is the most fundamental factor.

- Working Load: Calculate the maximum static tension the chain will experience.

- Shock Loads: Estimate the magnitude and frequency of any sudden impact loads (e.g., from starting, stopping, or shifting loads). The chain must have a Working Load Limit (WLL) with a safety factor that adequately accounts for these peaks.

- Load Type: Is the load constant, intermittent, or alternating (push-pull)? This affects fatigue life calculations.

-

Operational Speed and Duty Cycle: While leaf chains are not designed for high speeds, the rate of articulation and the frequency of use matter.

- High-Cycle Applications: Machines with very frequent start-stop cycles (e.g., packaging equipment) require chains with excellent fatigue resistance, often achieved through processes like shot peening.

- Low-Speed, High-Load Applications: For slow-moving but heavy loads (e.g., cranes), the primary focus is on ultimate tensile strength and wear resistance.

-

Operating Environment: The conditions in which the chain operates can be as important as the load itself.

- Contaminants: Exposure to abrasive dust (cement, grain), corrosive chemicals, or salt water necessitates special consideration. Chains with enhanced sealing, special coatings (like zinc or nickel plating), or even stainless steel construction may be required.

- Temperature: Standard chains are designed for ambient temperatures. High-temperature environments (e.g., near furnaces) require special heat-resistant steels, while very low temperatures can embrittle standard materials.

- Lubrication Constraints: In food, pharmaceutical, or textile applications where lubricant contamination is a concern, self-lubricating chains (with polymer bushings) or approved food-grade lubricants must be used.

The following table provides a quick-reference guide for the selection logic:

| Primary Factor |

Consideration |

Selection Influence |

| High Static/Shock Load |

Maximum force applied |

Select a higher WLL; ensure robust safety factor (e.g., 6:1 or 8:1 for lifting). |

| High-Cycle, Repetitive Use |

Fatigue life |

Prioritize chains from manufacturers that specify fatigue ratings and use shot peening. |

| Abrasive Environment |

Accelerated wear |

Look for hardened chains, special coatings, and ensure excellent sealability for lubrication. |

| Corrosive Environment |

Rust and chemical attack |

Specify stainless steel or coated chains. Increase lubrication frequency. |

| Extreme Temperatures |

Material properties |

Require special alloy steels rated for the specific temperature range. |

7.2. Common Mistakes to Avoid

Several pitfalls can lead to premature failure or unsafe conditions:

- Selecting Based on Price Alone: The cheapest chain often has lower-grade materials, less precise heat treatment, and poorer fatigue performance, leading to higher long-term costs through downtime and replacements.

- Ignoring the Full Safety Factor: Using a chain’s Ultimate Tensile Strength (UTS) instead of its Working Load Limit (WLL) for design is a critical and dangerous error. Always apply the correct safety factor for the application.

- Mixing Chains from Different Manufacturers: Even chains with the same nominal size (e.g., AL 82x4) can have slight dimensional variations between brands. Mixing them can cause uneven load distribution and accelerated wear.

- Neglecting Environmental Factors: Using a standard, uncoated chain in a corrosive environment will drastically shorten its life, regardless of its load capacity.

- Incorrect Installation and Alignment: A chain that is misaligned on its sprockets will experience side-loading, causing uneven wear, noise, and dramatically reduced lifespan.

8. Environmental and Safety Considerations

The use of leaf chains extends beyond pure performance to encompass broader responsibilities regarding environmental impact and, most critically, workplace safety. Proper attention to these factors ensures not only the longevity of the equipment but also the protection of personnel and the environment.

8.1. Longevity and Sustainability of Materials

The inherent durability of leaf chains contributes directly to sustainability by reducing resource consumption and waste.

- Design for Longevity: A high-quality, properly maintained leaf chain can last for thousands of operating hours. This long service life means fewer replacements, which translates to reduced material usage, manufacturing energy, and end-of-life waste over the lifetime of a machine.

- Material Efficiency: The trend towards high-strength steels allows for chains with the same load capacity but a smaller cross-section, using less raw material without compromising performance.

- Recyclability: At the end of its service life, a standard steel leaf chain is almost entirely recyclable. The steel can be melted down and repurposed, minimizing its environmental footprint. This circular economy aspect is a key consideration for environmentally conscious manufacturers.

- Lubrication Impact: The choice of lubricant also has environmental implications. The development of biodegradable lubricants and the prevention of lubricant leakage into the environment (e.g., in food processing or outdoor applications) are increasingly important.

8.2. Safety Standards and Regulations

Given their critical role in lifting and moving heavy loads, leaf chains are governed by stringent international safety standards and regulations. Compliance is not optional; it is a legal and ethical imperative.

- Lifting Equipment Directives: In many regions, equipment using leaf chains for lifting (e.g., forklifts, cranes) falls under strict regulations such as the EU Machinery Directive or OSHA (Occupational Safety and Health Administration) regulations in the United States.

- Chain-Specific Standards: Organizations like the American Society of Mechanical Engineers (ASME) publish standards such as ASME B29.8, which specifies the dimensions, capacities, and mechanical properties for leaf chains. Using chains that are manufactured and certified to these standards is the baseline for ensuring safety.

- Working Load Limit (WLL) and Safety Factor: These standards mandate the minimum safety factors that must be applied. For lifting applications involving personnel or critical loads, safety factors are typically 5:1, 6:1, or even 8:1. This means the chain’s minimum breaking strength is 5 to 8 times greater than its rated WLL.

The table below summarizes the safety hierarchy for leaf chains:

| Safety Level |

Key Principle |

Implementation |

| Inherent Design Safety |

Built-in strength exceeding the application’s needs. |

Selecting a chain with the correct WLL and safety factor per ASME/ISO standards. |

| Operational Safety |

Using the component within its intended limits. |

Adhering to rated loads, avoiding shock loads, and ensuring proper alignment. |

| Procedural Safety |

Actions taken to monitor and maintain integrity. |

Implementing regular inspection, lubrication, and replacement schedules. |

8.3. Proper Handling and Replacement Schedules

Safety is ultimately enforced through diligent daily practices. A chain that is mishandled or used beyond its wear limits is a safety hazard.

-

Proper Handling:

- Inspection upon Receipt: Always inspect a new chain for any shipping damage or manufacturing defects before installation.

- Avoiding Damage: Never drag chains over sharp edges, weld on them, or subject them to modification. This can create stress points that lead to catastrophic failure.

- Correct Installation: Ensure the chain is correctly routed and connected with the proper, rated attachment hardware.

-

Replacement Schedules:

- Wear Elongation as the Primary Metric: The most objective measure for replacement is wear elongation. As per industry best practice, a chain should be replaced once its length increases by 2-3% over its original length. Measuring pitch elongation with a chain wear gauge is the most accurate method.

- Regular Visual Inspections: Operators should be trained to look for signs of damage, including:

- Cracks or nicks in the link plates.

- Seized or stiff links that do not articulate freely.

- Visible wear grooves on the pins or plate holes.

- Signs of corrosion or pitting.

- Documented Schedules: For critical applications, maintain a log of operating hours and inspections to predict and plan for replacement before a failure occurs, transitioning from reactive to proactive maintenance.

In summary, treating a leaf chain with the respect its critical role demands—through mindful material selection, strict adherence to standards, and rigorous maintenance—is the foundation of a safe and sustainable industrial operation.

9. Conclusion

9.1. Recap of Leaf Chains’ Significance in Industrial Applications

From the bustling warehouse floor to the heart of the heavy-duty production line, the leaf chain has firmly established itself as an indispensable component in the industrial landscape. As we have explored, its significance is not derived from complexity, but from its masterful simplicity and unwavering reliability. Its robust, pin-and-plate design is uniquely engineered to excel where it matters most: in applications demanding high tensile strength, precise load control, and durability under strenuous, often slow-moving conditions. Whether silently lifting multi-ton loads in a forklift mast, synchronizing high-speed packaging machinery, or pulling heavy conveyors, the leaf chain performs its critical duty as a true unsung hero of power transmission. Its role in enabling safe and efficient lifting, conveying, and specialized power transmission is a testament to a design philosophy where brute strength and engineered precision converge.

9.2. Future Prospects and Technological Advancements

The future of the leaf chain is not one of obsolescence, but of continuous evolution. As Industry 4.0 accelerates, the leaf chain is poised to become smarter, stronger, and more integrated. The ongoing development of advanced materials, including new high-strength alloys and composite treatments, promises chains that are even lighter and more durable, contributing to greater energy efficiency in machinery. Furthermore, the integration of IoT-enabled monitoring systems will transform maintenance paradigms, shifting from scheduled inspections to real-time, predictive health monitoring. This data-driven approach will virtually eliminate unplanned downtime and enhance safety to unprecedented levels. Far from being a relic of the industrial age, the leaf chain is adapting to the demands of the digital one, ensuring it will continue to be a fundamental, albeit smarter, backbone of industrial motion for decades to come.