Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsIn the world of industrial machinery and heavy-duty equipment, the humble chain is a workhorse. While many are familiar with standard roller chains, a specific type of chain is critical for applications demanding immense strength in a compact package: the leaf chain. And when operating environments are harsh and corrosive, the material choice becomes paramount. This is where stainless steel leaf chains become an indispensable component.

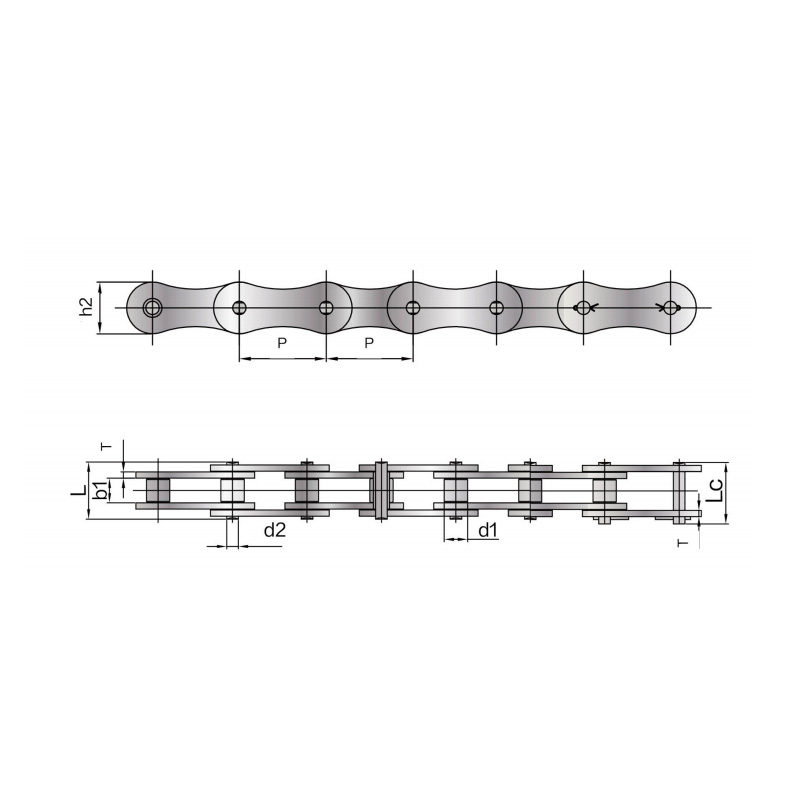

First, it’s crucial to distinguish a leaf chain from a standard roller chain. A leaf chain, also known as a cable chain or balance chain, has a simple yet robust design. It is constructed of side plates (or link plates) held together by pins. The key difference is the absence of rollers and bushings.

This design allows the chain to articulate, or pivot, only at the pin joints. This makes it exceptionally strong in tension—meaning it can withstand very high pulling forces—but it is not designed to run over sprockets at high speeds like a roller chain. Its primary function is linear, straight-pull lifting or balancing.

When this design is manufactured from stainless steel alloys, it inherits a suite of properties that make it suitable for challenging environments.

The decision to use a stainless steel leaf chain over a carbon steel chain is driven by environmental factors and performance requirements. The core benefits include:

Superior Corrosion Resistance: This is the most significant advantage. Stainless steel chains are highly resistant to rust and degradation caused by water, chemicals, solvents, salt spray, and high humidity. This makes them ideal for:

High Strength-to-Weight Ratio: Despite their resistance to corrosion, specific grades of stainless steel (like 304 and 316) offer excellent tensile strength. They can handle heavy loads, making them perfect for lifting applications and tensioning systems.

Hygienic and Easy to Clean: The smooth, non-porous surface of stainless steel prevents bacteria, mold, and contaminants from embedding themselves. This allows for easy and effective sterilization through steam cleaning or high-pressure washdowns, which is a non-negotiable requirement in sanitary environments.

Durability with Minimal Maintenance: While no chain is entirely maintenance-free, a corrosion-resistant chain like those made from stainless steel requires significantly less attention. They do not need the frequent oil-based lubrication that carbon steel chains do, which can attract dirt or contaminate products. This reduces downtime and long-term maintenance costs.

Temperature Resistance: Stainless steel leaf chains generally perform better across a wider temperature range than their carbon steel counterparts, particularly in applications involving steam or elevated ambient temperatures.

The unique combination of high strength and corrosion resistance opens up a wide array of industrial applications for these chains.

Choosing the correct chain is critical for safety and performance. Here are the key factors to consider:

Load Capacity: This is the most important factor. You must know the maximum static and dynamic loads the chain will experience. Always select a chain with a working load limit (WLL) that exceeds your maximum anticipated load, incorporating a significant safety factor. Never exceed the manufacturer’s rated capacity.

Stainless Steel Grade: Not all stainless steel is the same.

Attachment Styles: Leaf chains are often supplied with specialized attachments (e.g., clevis ends, hook ends, or master links) for easy connection to equipment. Ensure the attachment style and its load rating are suitable for your system.

Environmental Factors: Consider the specific contaminants, temperature extremes, and type of cleaning the chain will be subjected to. This will guide your choice between 304 and 316 grades.

Lubrication: While stainless steel chains require less lubrication, some applications may benefit from a food-grade or synthetic lubricant to reduce wear and prevent galling (a form of wear that can occur between two metal surfaces).

Even the best chain will fail if improperly installed or neglected.

A stainless steel leaf chain is a premium solution for demanding applications where strength, reliability, and corrosion resistance are paramount. While the initial investment may be higher than carbon steel, the payoff in reduced maintenance, longer service life, and prevention of costly downtime and contamination makes it a wise and often essential choice. By understanding their properties, applications, and selection criteria, you can ensure you choose the right chain to keep your operations running smoothly and safely, even in the toughest conditions.