Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

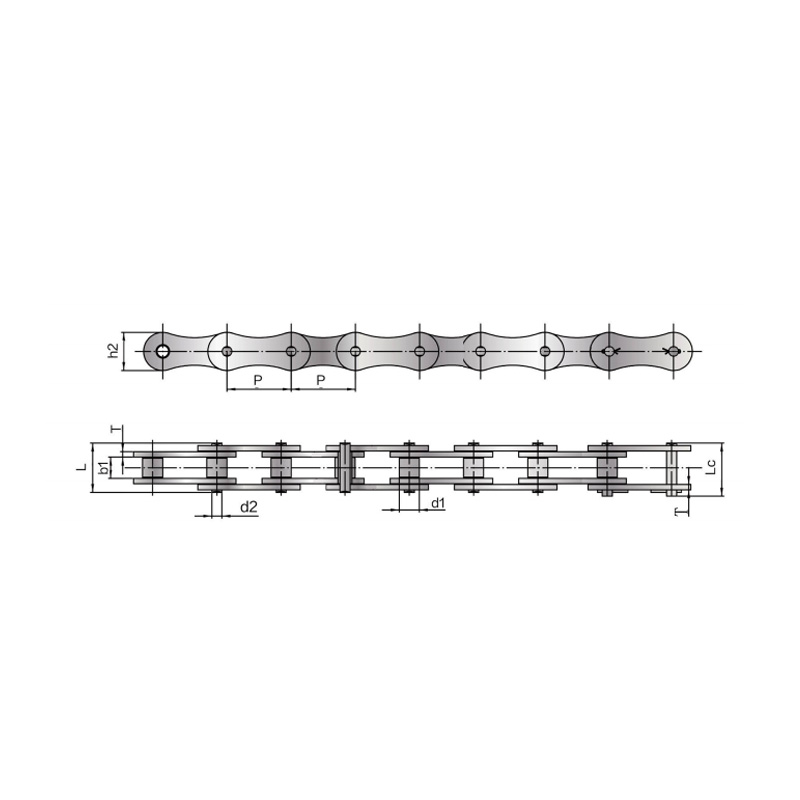

See DetailsDrive chains are an essential component in many mechanical systems, transmitting power between shafts in applications ranging from industrial machinery to agricultural equipment. Their performance and longevity are influenced by various factors, including load, speed, lubrication, and environmental conditions. One common concern is whether drive chains can operate effectively in dusty or dirty environments.

Dusty or dirty environments present unique problems for drive chains. Particles such as dust, sand, metal shavings, or other debris can accumulate on the chain and its associated sprockets. This accumulation leads to several potential issues:

These factors can shorten the service life of drive chains and, if left unaddressed, may lead to unexpected downtime and costly repairs.

Not all drive chains respond the same way to harsh environments. Certain types of chains are better suited for dusty or dirty conditions:

Selecting the right chain type is crucial. Using a standard roller chain in an environment with heavy dust or dirt is likely to result in frequent maintenance and early failure.

Even the best chains can suffer if maintenance and preventive measures are neglected. The following strategies can help drive chains operate effectively in dirty environments:

Lubrication reduces friction and wear while also acting as a barrier against contaminants. In dusty conditions, the following practices are recommended:

Mechanical guards or covers can shield drive chains from direct exposure to dust and debris. Enclosures can be simple metal guards or fully enclosed chain cases. While they add cost and complexity, they significantly extend chain life in harsh environments.

Cleaning drive chains removes abrasive particles that accumulate over time. This can be done using brushes, low-pressure air, or mild solvents. It’s important to clean chains carefully to avoid damaging the links or dislodging lubrication entirely.

Chains operating in dirty environments may experience accelerated wear, leading to slack or misalignment. Regularly checking and adjusting chain tension ensures smooth operation and reduces the risk of slippage or premature failure.

Frequent visual inspections help detect early signs of wear, stretching, or damage. Early detection allows for timely maintenance or replacement, preventing unexpected downtime.

While drive chains can operate in dusty or dirty conditions, there are limits to their durability. Excessive dust, abrasive particles, or exposure to moisture combined with dirt can still reduce lifespan significantly. In extremely harsh environments, alternative power transmission methods such as belts, enclosed gear drives, or even hydraulic systems may provide more reliable performance. However, these alternatives come with their own trade-offs in terms of efficiency, cost, and maintenance requirements.

Drive chains can operate in dusty or dirty environments, but their performance and longevity depend on proper chain selection, protective measures, and diligent maintenance. Enclosed or sealed chains, appropriate lubrication, protective covers, regular cleaning, and routine inspections all contribute to reliable operation. While challenges exist, understanding the risks and implementing preventive strategies allows drive chains to remain an effective power transmission solution even in harsh conditions.

By approaching drive chain maintenance proactively, operators can minimize downtime, reduce repair costs, and ensure smooth operation in environments that might otherwise be considered hostile to standard mechanical components.