Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

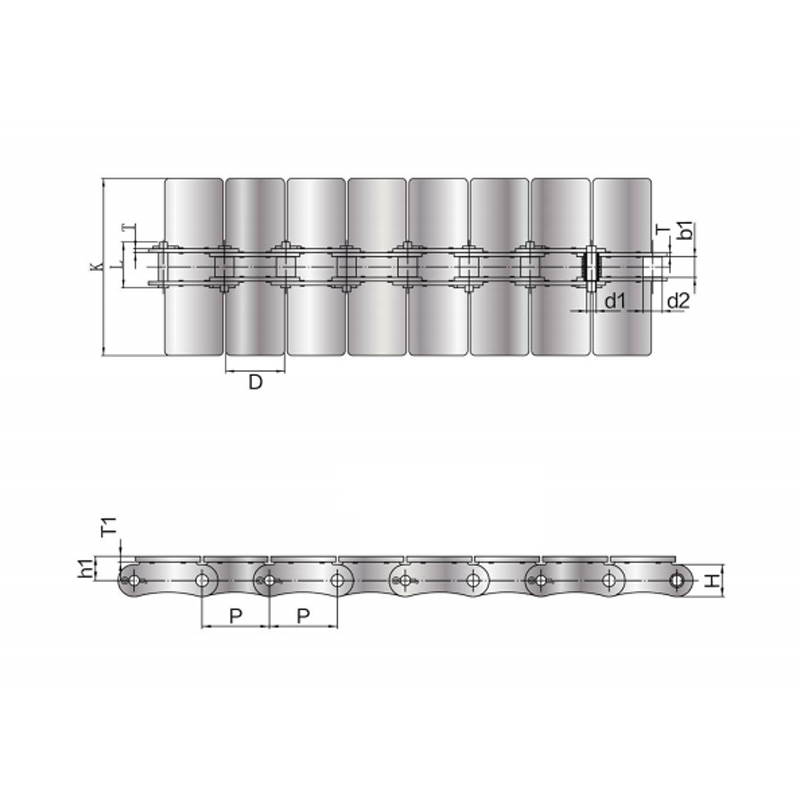

See DetailsFlat top chains are widely used in material handling and conveyor systems across numerous industries, from food processing to automotive manufacturing. They are a type of conveyor chain designed to provide a smooth, continuous surface for transporting products, making them highly efficient for handling bulky, irregular, or delicate items. However, within the category of flat top chains, there are different designs, the most notable being welded flat top chain and regular flat top chains. Understanding the differences between these two types is essential for selecting the right chain for a specific application, optimizing performance, and ensuring long-term reliability.

A regular flat top chain is a conveyor chain that consists of interlinked metal or plastic modules, forming a flat surface. These chains typically include connecting pins and links that allow flexibility, enabling the chain to bend around sprockets and guide rails. They are designed to support the transport of various products smoothly and are commonly made from stainless steel, carbon steel, or engineered plastics.

Regular flat top chains are widely favored for their modularity. The modular design allows individual segments to be replaced when worn or damaged, reducing overall maintenance costs. They are also adaptable, as sections of the chain can be added or removed to adjust the length of a conveyor system without replacing the entire chain.

Key characteristics of regular flat top chains include:

Welded flat top chains are a specific type of flat top chain distinguished by their construction. As the name suggests, the links of these chains are welded together, forming a solid, continuous structure rather than modular segments connected by pins. Welding provides enhanced strength and rigidity, making these chains particularly suitable for heavy-duty applications.

Unlike regular flat top chains, welded flat top chains are generally designed for demanding industrial environments where high loads, high temperatures, or abrasive conditions may exist. The welding process ensures that each link is permanently fixed, reducing the risk of pin wear or joint failure over time.

Key characteristics of welded flat top chains include:

The primary distinction between welded and regular flat top chains lies in how they are constructed. Regular flat top chains use pins, connecting links, or rivets to join the chain segments. This modular construction offers flexibility but can introduce points of wear, particularly under heavy or abrasive loads. Over time, the pins and joints may stretch or deform, potentially affecting chain performance.

In contrast, welded flat top chains eliminate these movable joints by fusing the links together. This creates a rigid structure capable of withstanding higher stress without deformation. Welding also improves alignment, ensuring that the flat top surface remains even and stable, which is crucial for precise handling of products such as boxes, cans, or delicate components.

From a manufacturing perspective, producing a welded flat top chain involves more complex processes than assembling modular chains. Each link must be accurately cut, shaped, and welded to maintain uniformity. While this can increase production costs, the result is a chain designed for long-term performance in demanding industrial settings.

One of the most noticeable differences between welded and regular flat top chains is load capacity. Regular flat top chains are designed to handle moderate loads efficiently. However, under very heavy loads or frequent impact, the joints between modular segments can experience wear or elongation, potentially leading to chain failure if not monitored.

Welded flat top chains, by comparison, are ideal for heavy-duty applications. The welded links provide higher tensile strength and better load distribution across the chain, minimizing stress on individual sections. This makes welded flat top chains suitable for industries such as automotive, metalworking, and bulk material handling, where heavy or sharp-edged products may be transported continuously.

In terms of durability, welded chains generally outperform modular chains in harsh environments. They are less prone to fatigue at joints, less likely to accumulate dirt between links, and can tolerate high temperatures and chemical exposure better than standard chains. However, regular flat top chains remain the preferred choice in applications where flexibility and easy maintenance are more critical than extreme load capacity.

A key advantage of regular flat top chains is flexibility. Their modular construction allows them to bend around tight sprockets, corners, and inclined surfaces. They can also be resized easily by adding or removing modules. This adaptability is particularly valuable in industries where conveyor layouts frequently change or where the chain must navigate complex paths.

Welded flat top chains, while stronger, sacrifice some of this flexibility. Their rigid construction makes them better suited for straight or gently curved conveyor systems. While they can be engineered to accommodate slight curves, extreme bending or frequent adjustments are not practical. Therefore, welded chains are best used in stable, heavy-duty conveyor designs where the layout is unlikely to change.

Maintenance is another area where welded and regular flat top chains differ. Regular flat top chains require regular inspection and lubrication of pins and joints to prevent wear and ensure smooth operation. If a section becomes worn or damaged, it can be replaced individually, minimizing downtime and repair costs.

Welded flat top chains require less frequent maintenance because they have fewer moving parts. There are no pins or joints to wear out, reducing the risk of elongation or misalignment. However, if a welded chain is damaged, repairing it may be more difficult than replacing a modular section. In many cases, an entire welded chain segment may need replacement.

In terms of longevity, welded chains generally outlast regular chains in high-load or harsh conditions, while regular chains offer a longer effective lifespan in applications where flexibility and ease of maintenance are more critical.

Both welded and regular flat top chains are versatile, but their applications often differ based on the properties outlined above.

Regular flat top chains are commonly used in:

Welded flat top chains are typically found in:

Understanding these application differences helps industries select the most suitable chain, balancing load requirements, maintenance capabilities, and system design.

Cost is another factor to consider. Regular flat top chains are generally more affordable initially, partly due to their modular construction and simpler manufacturing process. Maintenance costs are manageable, but frequent inspection and lubrication are necessary to maximize lifespan.

Welded flat top chains may have a higher upfront cost due to the complexity of welding and material requirements. However, the reduced maintenance frequency, increased durability, and higher load capacity can make them more cost-effective in demanding applications over time.

| Feature | Regular Flat Top Chain | Welded Flat Top Chain |

| Construction | Modular, linked with pins or rivets | Links welded into continuous structure |

| Flexibility | High, suitable for curves and inclines | Moderate, best for straight paths |

| Load Capacity | Moderate | High |

| Maintenance | Regular inspection, lubrication, module replacement | Less frequent maintenance, harder to repair |

| Durability | Moderate, joints may wear | High, resistant to fatigue and stress |

| Application | Light to medium-duty conveyors | Heavy-duty, high-load conveyors |

| Cost | Lower initial cost | Higher initial cost, potentially lower lifetime cost |

Choosing between a welded flat top chain and a regular flat top chain depends on the specific requirements of a conveyor system. If high strength, durability, and low maintenance are priorities, especially in heavy-duty or harsh environments, a welded flat top chain is usually the better choice. On the other hand, if flexibility, modularity, and ease of maintenance are more important, a regular flat top chain is likely the more suitable option.

By understanding these differences, engineers, plant managers, and operations teams can make informed decisions, ensuring their conveyor systems operate efficiently, safely, and reliably over time. While both types of chains have their advantages, the best choice ultimately depends on the application, load requirements, and operational priorities.