Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsDrive Chains, namely transmission chains, are a kind of power transmission device widely used in the mechanical field. Through the coordination of a series of chain links and sprockets, it can efficiently transfer power from one component to another, playing a crucial role in numerous industries.

The structure and working principle of the transmission chain

1. Basic structure:

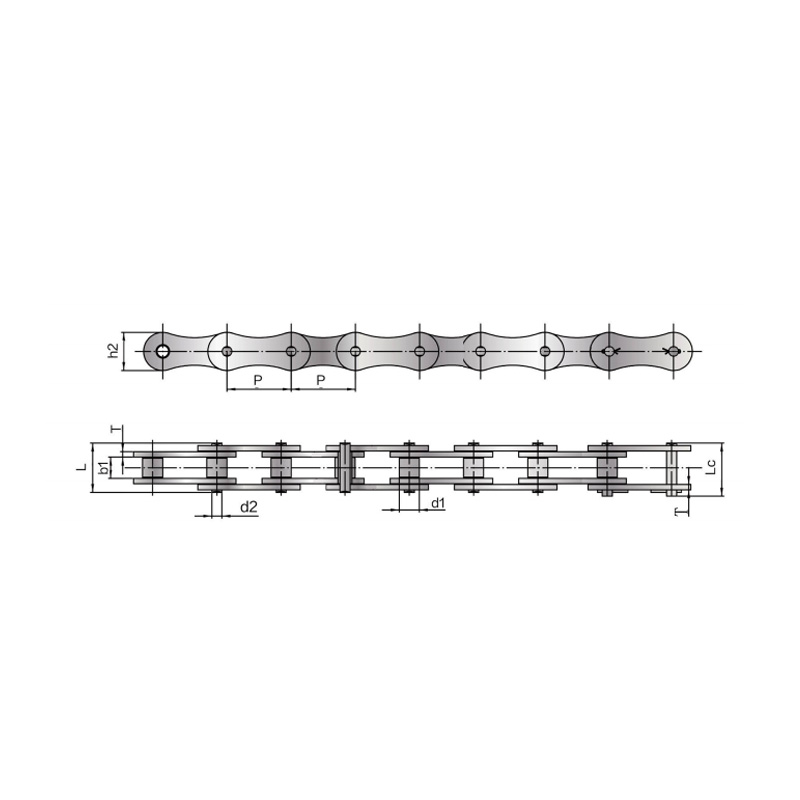

Chain link: The basic component unit of a transmission chain, usually consisting of inner chain plates, outer chain plates, pins, sleeves and rollers, etc. The inner chain plate and the outer chain plate are connected by pins to form a flexible chain link structure, providing flexibility for the chain.

Roller: Installed on the sleeve, it is located at the meshing part between the chain link and the sprocket. When the chain cooperates with the sprocket, the rollers roll in the tooth grooves of the sprocket, which can effectively reduce friction and wear and improve the transmission efficiency.

Sprocket: A wheel with a specific tooth profile that meshes with the chain. The sprocket is fixed to the shaft through a key or other connection methods. When the shaft rotates, the sprocket drives the chain to move, thereby achieving the transmission of power.

2. Working Principle: The working principle of the transmission chain is based on the meshing transmission between the sprocket and the chain. When the active sprocket starts to rotate under the drive of the power source, its tooth profile interlocks with the links of the chain, driving the chain to move in a straight line. As the chain is a continuous circular structure, it will move in a cycle around each sprocket, thereby driving the driven sprocket to rotate and transmitting power to the required part. During this process, the rolling of the rollers plays a role in reducing friction and buffering impact force, making the transmission process smoother and more efficient.

The application fields of the transmission chain

1. Industrial field:

In manufacturing, on production lines, drive chains are often used to drive conveyor belts, elevators and other equipment, achieving the transportation of materials and the circulation of products. For instance, in the final assembly line of an automotive manufacturing plant, the transmission chain drives the conveyor belt to accurately transport components to each assembly station.

In the mining industry, large equipment such as excavators, loaders and crushers in mines all need to rely on transmission chains to transmit power. These devices usually need to withstand huge loads, and the high strength and durability of the transmission chain are sufficient to meet their working requirements.

2. Transportation field:

Bicycles and motorcycles: These are among the most common applications of transmission chains. In a bicycle, the pedals drive the rear wheels to rotate through sprockets and chains, enabling the vehicle to move forward. The transmission chain of a motorcycle transmits the power of the engine to the rear wheels, providing driving force for the vehicle.

In the engine timing system of a car, the transmission chain plays a crucial role. It precisely transmits the rotation of the crankshaft to the camshaft, ensuring that each cylinder of the engine can perform the intake, compression, power and exhaust strokes in the correct sequence, thus guaranteeing the normal operation of the engine.

3.Other fields:

In the logistics and transportation industry, automated shelves and sorting equipment in warehousing and logistics centers often use transmission chains for power transmission to achieve rapid handling and sorting of goods.

In the food and beverage industry, in food processing and packaging equipment such as filling machines and labeling machines, transmission chains are used to drive various transmission components, ensuring the precise operation of the equipment while meeting the food industry's requirements for hygiene and reliability.

Maintenance and care of the transmission chain

Regular inspection: Regularly check the wear of the chain, especially the connection points of the chain links and the surface of the rollers. The dimensions of the chain links can be measured with tools such as calipers and compared with the original specifications. When the wear exceeds a certain limit, the chain should be replaced in time to prevent problems such as tooth skipping and chain detachment.

Cleaning and lubrication: Keep the chain clean and regularly remove dust, oil stains and other impurities from the surface of the chain. At the same time, the chain should be lubricated at the prescribed intervals. Use suitable lubricating oil or grease and apply it evenly to all parts of the chain to reduce friction and extend the service life of the chain.

Adjust the tension: During use, the chain may elongate due to wear and other reasons, and its tension needs to be adjusted regularly. It is generally achieved by adjusting the position of the sprocket or using a tensioning device to ensure that the chain has an appropriate tension. It should neither be too loose to cause tooth skipping nor too tight to increase transmission resistance and component wear.

The development trend of the transmission chain

Improvement of materials and processes: With the continuous development of materials science and manufacturing processes, new types of high-strength, wear-resistant and corrosion-resistant materials will be increasingly applied in the manufacturing of transmission chains. Meanwhile, advanced processing techniques such as precision forging and surface treatment will further enhance the quality and performance of the transmission chain, enabling it to adapt to more severe working environments and higher transmission requirements.

Intelligence and Automation: Future transmission chains will place greater emphasis on intelligence and automation. For instance, by installing sensors on the chain, the operating status of the chain, such as temperature, vibration, wear and other parameters, can be monitored in real time, and the data can be transmitted to the control system. Once an abnormal situation is detected, the system can automatically take measures, such as shutdown and alarm, and automatic adjustment, to enhance the reliability and safety of the equipment.

Green and environmental protection: Against the backdrop of increasingly enhanced environmental awareness, the development of transmission chains will also move towards a green and environmentally friendly direction. Developing low-noise and low-energy consumption transmission chain products to reduce environmental pollution and energy consumption will be one of the important development directions for the transmission chain industry in the future.

Conclusion

As an important power transmission device, the transmission chain plays an irreplaceable role in various fields. With the continuous advancement of technology, transmission chains will constantly innovate and develop in aspects such as structural design, material selection, and manufacturing processes to meet the growing demands of various industries. At the same time, we also need to attach importance to the maintenance and upkeep of the transmission chain to ensure that it always remains in good working condition and provide a strong guarantee for the stable operation of various mechanical equipment.