Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsIn the intricate machinery of modern industry, where seamless motion and unyielding power are paramount, drive chains operate as the silent force behind the scenes. These mechanical stalwarts transmit torque with remarkable efficiency, playing a critical role in everything from agricultural equipment to heavy-duty conveyors and motorcycles. Despite their understated appearance, drive chains are a cornerstone of kinetic reliability and mechanical precision.

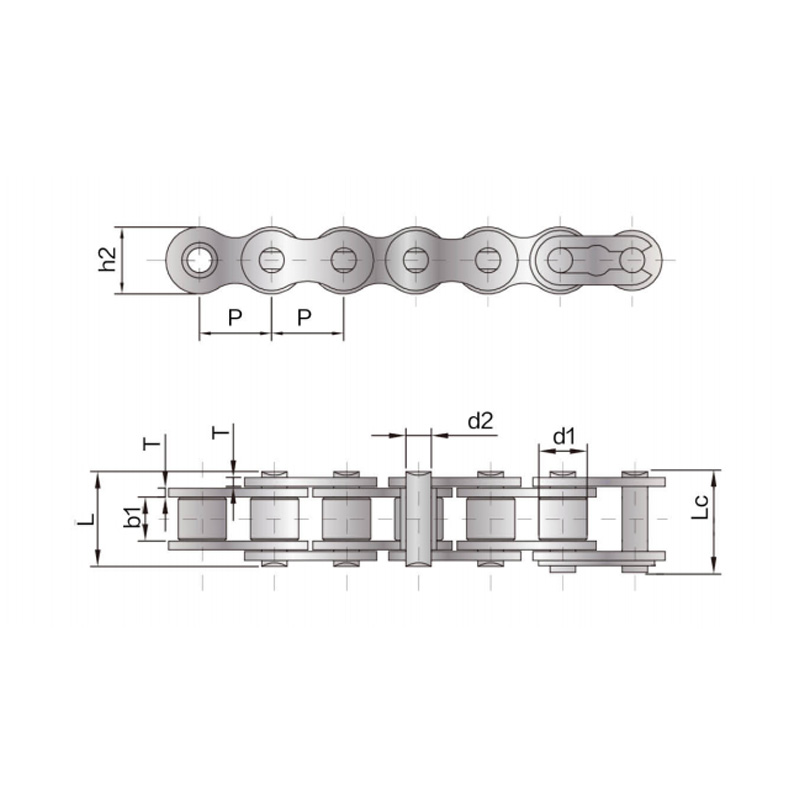

At their core, drive chains are assemblies of interconnected links, meticulously engineered to mesh with sprockets and transfer rotational energy. This seemingly simple interaction belies a sophisticated interplay of materials science, load dynamics, and wear resistance. Whether in the factory floor or the open field, drive chains remain indispensable wherever dependable power transmission is non-negotiable.

Unlike belts, which may slip under load or degrade with environmental exposure, drive chains grip with authority. Their metal-on-metal engagement ensures consistent velocity ratios and eliminates the energy losses associated with slippage. For applications demanding high load capacities and endurance in unforgiving conditions, chains outperform other mechanical links by a considerable margin.

Chain drives are not monolithic in design. They come in various types—roller chains, leaf chains, silent chains, and more—each tailored to specific operational demands. Roller chains, perhaps the most ubiquitous, combine robustness with versatility. Found in both industrial and automotive settings, they handle fluctuating loads and high speeds with admirable poise. Leaf chains, on the other hand, shine in lifting and hoisting scenarios, prized for their tensile strength and compact build.

A defining advantage of drive chains is their mechanical efficiency. With transmission rates reaching up to 98%, they offer near-frictionless power transfer when properly maintained. This high-efficiency threshold is not merely an engineering marvel—it directly translates to reduced energy costs, prolonged machinery lifespan, and minimized downtime. In industries where every second of operation matters, such precision and dependability are invaluable.

But even the most resilient systems require diligence. Drive chains demand routine inspection, lubrication, and tension adjustments to operate at peak performance. Without proper upkeep, they are susceptible to elongation, corrosion, and sprocket misalignment. Yet when cared for correctly, chains can serve reliably for thousands of operational hours, far exceeding expectations and reducing long-term maintenance budgets.

Material composition also plays a pivotal role. High-strength carbon steel and alloy blends are standard for their resistance to fatigue and elongation. In corrosive environments, stainless steel or nickel-plated chains are deployed to combat rust and ensure long-term viability. For high-precision applications, heat-treated and shot-peened components provide an added layer of durability against wear and mechanical shock.

Noise reduction is another evolving frontier. Traditional chains, known for their metallic clatter, are now being engineered with quieter link profiles and advanced damping systems. The result is smoother, more subdued operation—an important consideration for automated facilities and consumer-facing machinery where acoustic pollution is a concern.

Environmental adaptability further cements the drive chain’s status as a mechanical workhorse. From icy tundras to searing foundries, chains function where rubber belts falter. Their resilience under extreme temperatures and resistance to oils, solvents, and abrasives make them a preferred choice in rugged terrains and harsh production lines.

The drive chain is more than just a component—it’s a conduit of controlled power. A marvel of simplicity and strength, it embodies the industrial ethos: do more, last longer, fail less. In an era increasingly obsessed with digital sophistication, this analog champion continues to prove that true performance is forged in steel and perfected through motion.