Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsIn the realm of industrial material handling, conveyor chains serve as the vital arteries that sustain operational fluidity. Among the myriad options available, stainless steel welded conveyor chains distinguish themselves as an unparalleled choice, marrying resilience with superior functionality. Engineered for rigorous environments, these chains embody a blend of strength, corrosion resistance, and precision craftsmanship that elevates industrial conveyance to a new echelon.

Unrivaled Strength and Structural Integrity

At the core of stainless steel welded conveyor chains lies a meticulous fabrication process that ensures exceptional robustness. The welding of individual chain links produces a monolithic structure that dramatically enhances tensile strength and fatigue resistance. Unlike mechanically assembled chains, welded variants minimize the risk of link failure or elongation under heavy loads, thereby extending the chain’s service life and reliability.

The choice of stainless steel alloy further amplifies these properties. Renowned for its superior tensile strength and toughness, stainless steel resists deformation and fracture even in the harshest mechanical conditions. This intrinsic strength renders welded conveyor chains particularly suited to industries where precision and dependability are non-negotiable, such as food processing, pharmaceuticals, and chemical manufacturing.

Corrosion Resistance: Defying the Elements

One of the defining virtues of stainless steel welded conveyor chains is their remarkable resistance to corrosion. The chromium-rich composition forms a passive oxide layer that acts as a formidable shield against oxidation and chemical degradation. This property is indispensable in environments saturated with moisture, acids, or other corrosive agents, where traditional carbon steel chains would succumb to rapid deterioration.

Consequently, these chains are ideally positioned for use in applications involving frequent washdowns, exposure to aggressive cleaning agents, or operations within corrosive atmospheres. Their capacity to maintain structural integrity and operational efficiency under such conditions significantly reduces maintenance costs and downtime, translating to tangible benefits for industrial stakeholders.

Precision Engineering for Optimal Performance

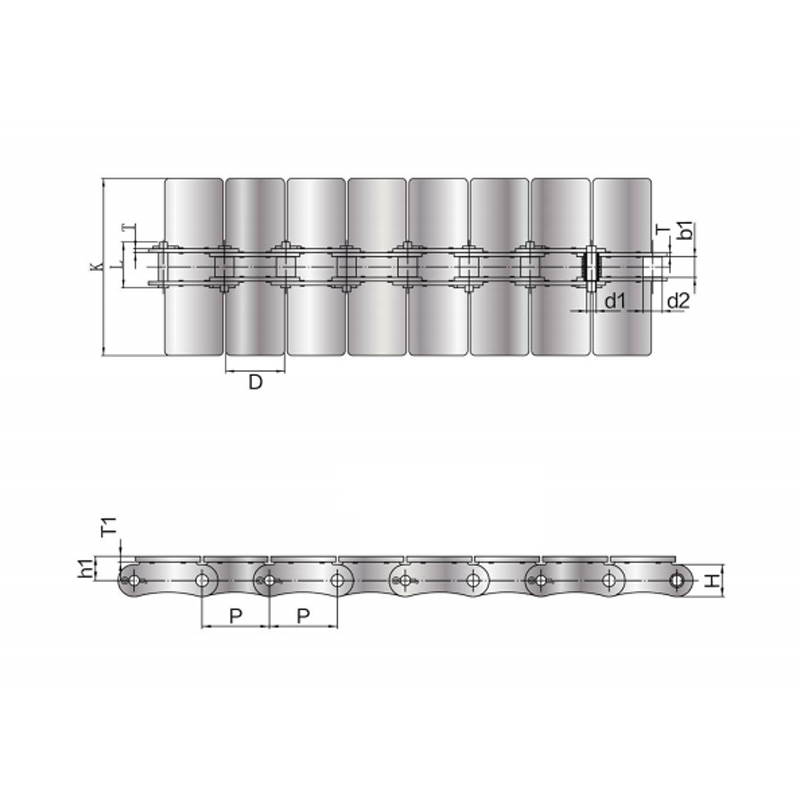

The manufacturing of stainless steel welded conveyor chains is a precise art that balances material science with mechanical engineering. Each link is crafted to exacting tolerances, ensuring uniformity in pitch, thickness, and articulation. This precision guarantees smooth operation, minimizes friction, and reduces wear on both the chain and associated machinery components.

Moreover, the welded construction eliminates pin and link movement that can cause slack or chain elongation over time. This stability results in consistent conveyance speeds and accurate load positioning, essential factors in automated and high-speed production lines where timing and synchronization are critical.

Versatility Across Diverse Applications

The adaptability of stainless steel welded conveyor chains spans an impressive spectrum of industrial domains. Their hygienic properties make them the chain of choice in food and beverage industries, where contamination control is paramount. In chemical plants, their corrosion resistance ensures uninterrupted operation amidst aggressive substances. Heavy manufacturing benefits from their load-bearing capacity, while packaging industries appreciate their smooth, noise-reducing performance.

Customization options further enhance their appeal. Chains can be tailored with various pitch sizes, attachments, and surface finishes to meet specific operational requirements, thereby delivering bespoke solutions that maximize efficiency and durability.

Sustainable and Cost-Effective Over Time

Though the initial investment in stainless steel welded conveyor chains may exceed that of conventional alternatives, their lifecycle economics favor long-term savings. Reduced frequency of replacements, minimized downtime, and lower maintenance interventions culminate in a superior return on investment. Additionally, the inherent recyclability of stainless steel aligns with sustainable manufacturing initiatives, supporting environmental stewardship without compromising industrial efficacy.

Stainless steel welded conveyor chains epitomize a sophisticated convergence of engineering excellence and material superiority. Their robust construction, unparalleled corrosion resistance, and precision design render them indispensable in demanding industrial applications. For enterprises seeking to optimize conveyor performance, enhance operational reliability, and safeguard against environmental challenges, these chains represent a strategic asset—one that delivers consistent value, durability, and efficiency across the board.