Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsIn the world of industrial engineering, few elements are as crucial yet as overlooked as metallurgy chains. These robust mechanical components are the silent sentinels of production, facilitating everything from mining operations to high-temperature manufacturing processes. To the untrained eye, they may seem like mere links of metal—but in truth, metallurgy chains are marvels of applied science, precision engineering, and strategic material selection.

At the heart of every metallurgy chain is a singular purpose: to endure. Whether hoisting tons of ore in subterranean mines or ferrying molten steel across smelting furnaces, these chains operate under conditions that would debilitate ordinary hardware. Their construction demands more than tensile strength; it requires metallurgical excellence. Alloys are meticulously chosen not just for hardness or resistance to abrasion, but for their behavior under thermal stress, their fatigue life, and their corrosion thresholds in hostile environments.

There are numerous varieties of metallurgy chains, each tailored to its operational role. Welded steel chains, for instance, dominate in environments where consistent load-bearing and resilience to deformation are essential. On the other hand, forged link chains are favored for their robustness and ability to withstand intermittent shock loads without compromise. Each variant is the product of extensive research and iterative design, where even minor alterations in geometry or composition can dramatically impact performance.

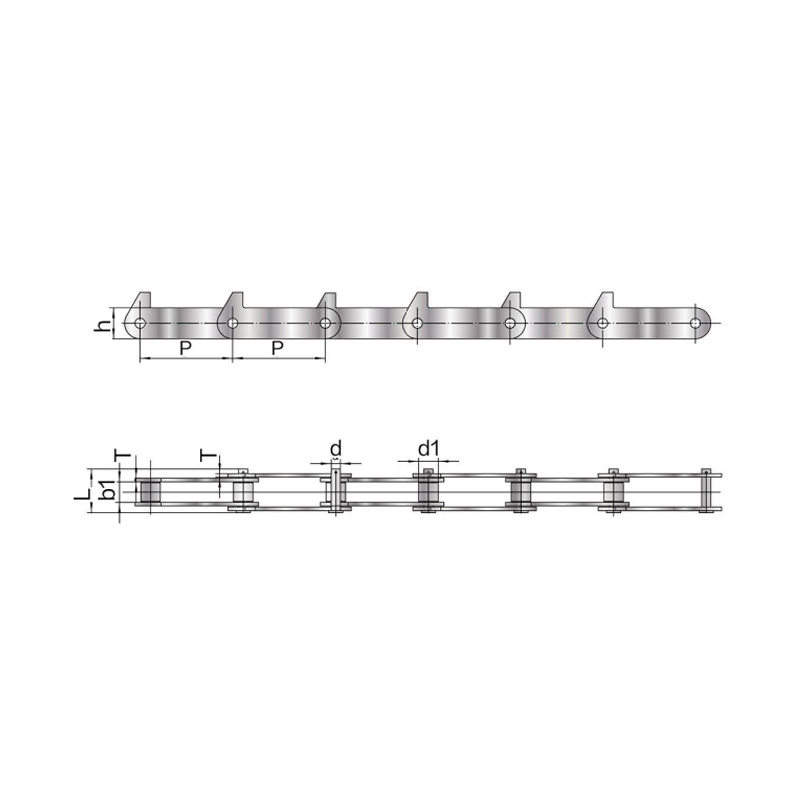

One of the defining characteristics of metallurgy chains is their adaptability to complex mechanical systems. In conveyor applications within foundries, these chains must align seamlessly with sprockets, rollers, and tensioners. Precision is paramount. A single misalignment can generate heat, increase friction, and precipitate failure—bringing entire production lines to a halt. Thus, manufacturers calibrate these chains to tolerances that flirt with perfection.

Yet strength and precision are only part of the equation. Longevity in metallurgy chains is achieved through sophisticated surface treatments and coatings. Case hardening, galvanization, and even ceramic overlay technologies are employed to combat the ravages of wear and oxidation. These enhancements are not cosmetic; they are existential. A chain that succumbs to rust or wear prematurely jeopardizes not only efficiency but safety—an unacceptable risk in high-stakes industries.

From an economic perspective, investing in high-performance metallurgy chains yields exponential returns. Downtime costs in heavy industries are measured in thousands—sometimes millions—per hour. Chains that extend mean time between failures (MTBF) translate into increased throughput and minimized maintenance disruptions. Moreover, the modern emphasis on sustainability places a premium on durability; components that last longer reduce material waste and lower the environmental footprint of operations.

The strategic importance of metallurgy chains becomes even more evident when considered in the context of global supply chains. As manufacturing ecosystems become increasingly interdependent, the reliability of individual components echoes through entire networks. A single chain failure in a mining facility in South Africa can delay production in an automotive plant in Germany. It’s a butterfly effect born not from chaos but from compromise—one that underscores the criticality of quality in foundational technologies.

Metallurgy chains are far more than utilitarian tools—they are pillars of industrial stability and enablers of engineering ambition. Forged in furnaces and perfected through decades of innovation, these components represent the quiet precision that drives progress. As industries evolve toward smarter, more efficient paradigms, metallurgy chains will remain essential: not as relics of the mechanical age, but as indispensable links in the chain of advancement.