Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsIn the realm of industrial machinery and mechanical conveyance, the demand for robust, reliable, and corrosion-resistant components has never been greater. Among these critical elements, stainless steel leaf chains have emerged as a quintessential solution, marrying extraordinary strength with remarkable resilience. Engineered to withstand extreme conditions and rigorous operational demands, these chains have become indispensable across diverse sectors including automotive, manufacturing, and material handling.

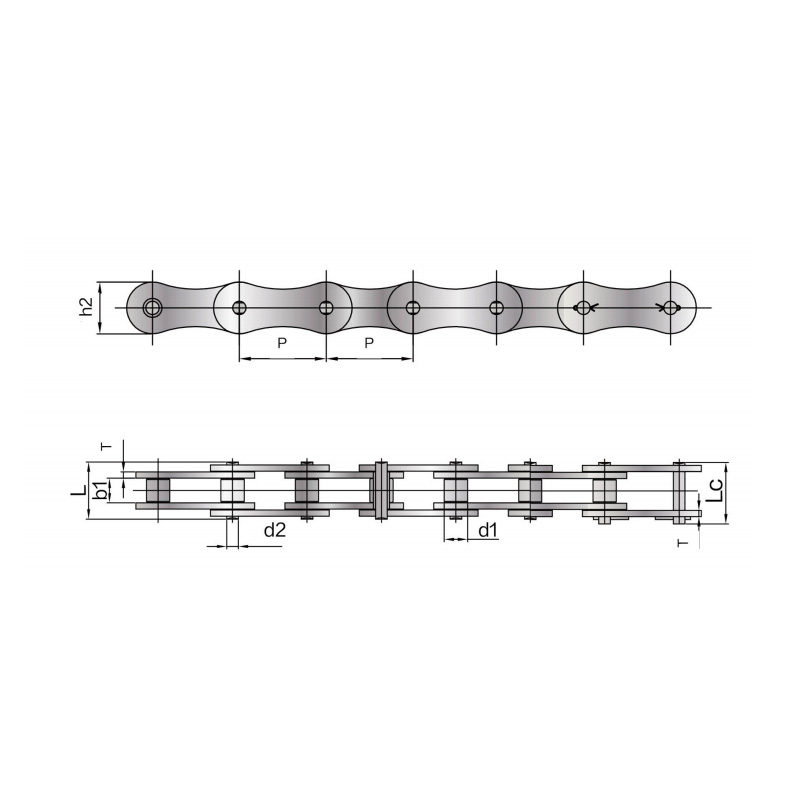

Leaf chains distinguish themselves from conventional roller chains by their unique construction. Rather than relying on rollers, they employ a series of flat, interlinked steel plates — the “leaves” — assembled in pairs to create a chain of exceptional tensile strength and flexibility. This architecture enables the chain to sustain substantial loads while maintaining smooth, low-friction motion, an essential characteristic for applications requiring precise vertical or horizontal power transmission.

What elevates stainless steel leaf chains above their carbon steel counterparts is their intrinsic resistance to corrosion, oxidation, and chemical exposure. Stainless steel alloys, typically grades 304 or 316, imbue the chains with unparalleled durability, particularly in environments where moisture, acids, or alkaline substances prevail. This corrosion resistance not only extends the lifespan of the chains but also drastically reduces maintenance intervals and costs, thereby optimizing operational uptime.

Industries operating in harsh environments—such as food processing, pharmaceuticals, and marine engineering—benefit immensely from these attributes. In food and beverage production, for instance, stainless steel leaf chains ensure hygiene compliance by resisting rust and contamination, facilitating easy cleaning and sterilization. Similarly, marine applications demand components that can endure saltwater exposure without degradation, a requirement impeccably met by stainless steel leaf chains.

Beyond their material composition, the precision engineering of these chains guarantees exceptional performance. The leaf plates are meticulously stamped and heat-treated to achieve a harmonious balance of hardness and toughness. This meticulous manufacturing process ensures the chain’s ability to resist elongation under heavy load, which is critical in maintaining consistent tension and avoiding premature failure in lifting or conveyor systems.

Customization options further enhance their appeal. Manufacturers often tailor leaf chain dimensions, tensile capacities, and finishing treatments to align perfectly with specific operational requirements. Whether it’s a heavy-duty crane hoist or a delicate assembly line conveyor, stainless steel leaf chains can be engineered to deliver exacting specifications, ensuring seamless integration and peak performance.

Moreover, their versatility extends to various configurations—single or multiple strands, coated or polished finishes—each offering unique advantages depending on application needs. Polished stainless steel, for example, not only improves corrosion resistance but also provides aesthetic appeal for visible components in architectural or design-centric machinery.

Stainless steel leaf chains epitomize industrial excellence, combining robust mechanical properties with exceptional environmental resistance. Their adaptability, longevity, and low maintenance requirements render them a superior choice for critical applications demanding unwavering reliability. For industries committed to operational efficiency and durability, investing in stainless steel leaf chains is not merely a choice but a strategic imperative that guarantees sustained performance in the most challenging conditions.