Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsIn the realm of mechanical motion, the driving chain is more than just a link between two points—it's the heartbeat of transmission systems in countless machines. Whether in motorcycles, bicycles, or industrial machinery, the driving chain plays a pivotal role in converting rotational motion into forward momentum. It’s a deceptively simple component, yet its engineering and utility are both intricate and indispensable.

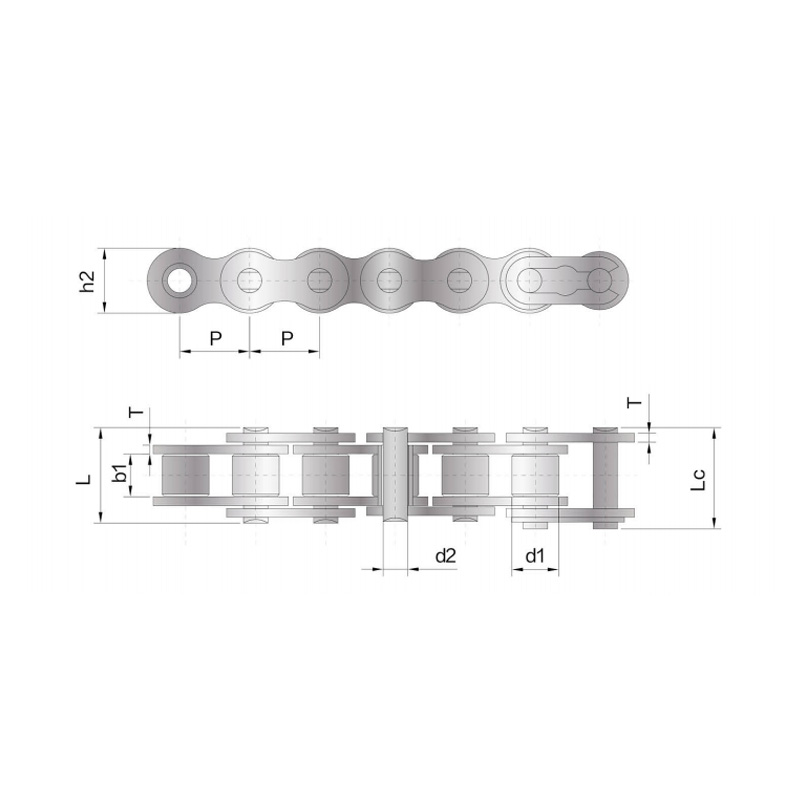

At its core, a driving chain is a sequence of interlinked metal components, engineered for strength, durability, and efficiency. It connects the driving sprocket—attached to the power source—to the driven sprocket, which transmits motion to the wheels or machinery. This basic design belies the complexity of its performance. A high-quality driving chain operates with minimal friction, sustains immense tension, and endures relentless repetition under varied conditions.

The materials used in manufacturing driving chains are no less significant than their design. Hardened steel, often alloyed for enhanced wear resistance, forms the backbone of most chains. Each link must withstand tensile loads and lateral pressure, all while maintaining precise articulation. Chains for high-performance applications, such as in motorsports or heavy industry, often undergo advanced treatments—heat tempering, surface coating, and even cryogenic hardening—to push their durability to the limit.

What distinguishes a superior driving chain from a mediocre one? Precision. Each component must fit together with microscopic accuracy. Any irregularity—be it a stretched link or a corroded pin—can result in inefficiency, mechanical failure, or worse, a catastrophic breakdown. That’s why regular maintenance is non-negotiable. Lubrication, tension adjustment, and periodic inspection extend the chain’s lifespan and preserve the machinery it powers.

But beyond mechanics, there’s strategy. Engineers and designers must choose the right type of driving chain for the application: roller chains, silent chains, or even toothed chains, each offering distinct advantages. Roller chains are widely used due to their balance of efficiency and cost-effectiveness, while silent chains provide smoother, quieter operation in high-speed environments.

Energy efficiency is another critical factor. A well-maintained driving chain can deliver more than 98% mechanical efficiency—far surpassing belt-driven systems in torque-heavy applications. This makes them a favored solution in settings where power delivery must be both robust and consistent.

However, chains are not without limitations. They are susceptible to wear from contaminants, require tensioning mechanisms, and can be noisy if not properly maintained. Despite these challenges, their mechanical reliability and versatility remain unmatched.

The driving chain is a marvel of applied mechanics—a testament to the power of simplicity when combined with precision engineering. It’s a component that rarely gets the spotlight, yet without it, motion grinds to a halt. Whether you’re optimizing industrial throughput or tuning a high-performance bike, never underestimate the importance of a well-engineered driving chain. It’s not just a mechanism; it’s the unsung hero of motion.