Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

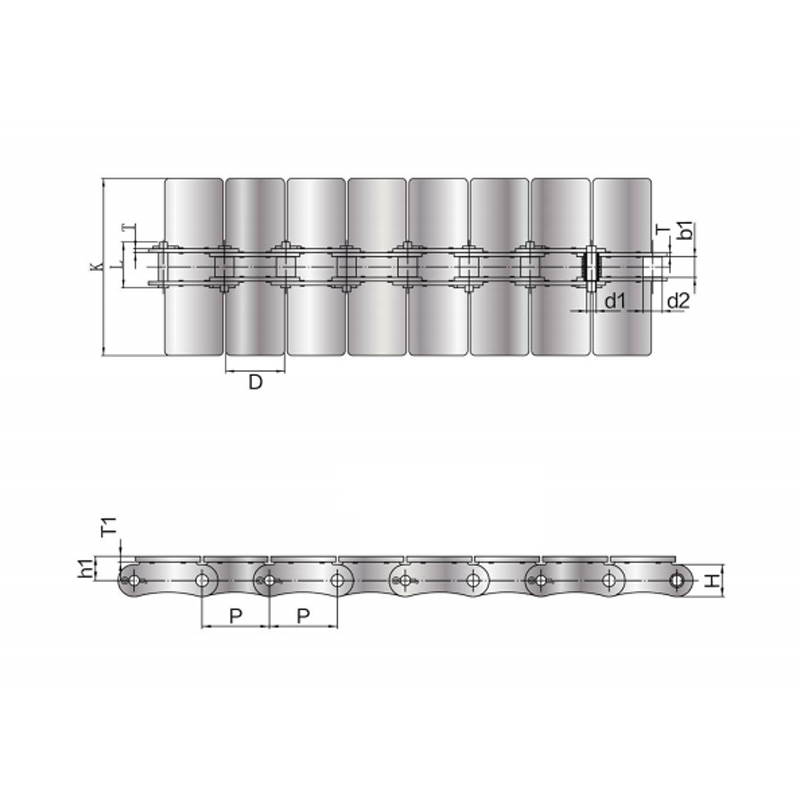

See DetailsIn the intricate world of industrial machinery, efficiency and reliability are paramount. The welded flat top chain has become a cornerstone for many industries, providing a robust, durable, and adaptable solution to diverse material handling needs. These chains, known for their unique design and superior performance, have earned a place in applications ranging from automotive manufacturing to food processing. But what exactly makes welded flat top chains indispensable? Let’s explore the reasons why these chains are an essential part of modern industrial operations.

Exceptional Durability and Strength

Welded flat top chains are engineered for endurance. Unlike traditional roller chains, which can wear down quickly under heavy load or constant stress, the welded construction of these chains provides an unparalleled level of strength. The interlinked plates are firmly welded together, ensuring a tight, rigid structure that can withstand significant mechanical forces. This robustness makes them particularly valuable in high-stress environments where other chains might falter. Whether it’s lifting heavy items in automated warehouses or transporting bulk materials in manufacturing plants, the welded flat top chain remains a reliable choice.

Versatile Design for Diverse Applications

One of the standout features of welded flat top chains is their adaptability. These chains come in various configurations, tailored to meet the unique demands of different industries. The flat top design allows for seamless and stable support for conveyed materials, preventing slippage and minimizing wear. This versatility means that welded flat top chains can be used in applications as varied as conveyor systems, packaging lines, and even heavy-duty industrial machines.

For example, in the food processing sector, where hygiene is critical, the welded flat top chain’s design facilitates easy cleaning. The smooth surface of the chain prevents food particles from getting trapped, ensuring that the chain remains sanitary. This adaptability also extends to temperature resistance, with many welded flat top chains engineered to perform efficiently in both extreme heat and cold, making them indispensable in refrigeration units, ovens, and other temperature-sensitive environments.

Reduced Downtime and Maintenance Costs

Maintenance is a significant concern for industries relying on continuous operations. The welded flat top chain, with its durable design, reduces the frequency of breakdowns and the need for regular repairs. Its high strength reduces wear and tear, meaning these chains can last longer than many alternatives. For businesses that rely on 24/7 production lines, the reduced downtime translates directly into higher productivity and lower operational costs.

Additionally, these chains often come with self-lubricating properties or can be easily equipped with lubrication systems, further enhancing their longevity and reducing maintenance effort. This combination of durability and ease of maintenance makes the welded flat top chain a cost-effective solution for industries with high-volume operations.

Increased Safety and Efficiency

When it comes to industrial applications, safety is always a priority. Welded flat top chains enhance operational safety by providing a smooth and stable surface for materials to rest on, reducing the risk of jams and equipment malfunctions. This reduces the likelihood of dangerous accidents that could occur from equipment failure or unexpected disruptions.

Moreover, the consistent performance of welded flat top chains allows for faster, more efficient production cycles. Their smooth operation minimizes friction, reducing the energy required to power machinery and ultimately lowering electricity costs. This boost in efficiency is critical for businesses seeking to optimize their energy consumption while maintaining high throughput.

Customizable for Specific Needs

Another compelling advantage of welded flat top chains is their customizability. Manufacturers can modify the chains to meet specific operational requirements, such as adjusting the width of the chain, altering the material for corrosion resistance, or modifying the design to accommodate specific load types. This customization ensures that companies can get a chain that fits their exact specifications, optimizing their system's performance and maximizing output.

A Vital Component for Industrial Success

Welded flat top chains are more than just a mechanical solution; they are a critical element in modern industrial efficiency. Their exceptional durability, adaptability, and ability to reduce maintenance make them indispensable across a variety of sectors. Whether for the heavy lifting needs of automotive assembly lines or the precise handling required in food processing, these chains provide an unmatched combination of strength, reliability, and safety. As industries continue to evolve, the welded flat top chain will remain a foundational component, enabling businesses to meet the challenges of the future with confidence.