Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsIn the dynamic world of industrial material handling, reliability and durability are paramount. Stainless steel welded conveyor chains stand as an indispensable component, engineered to deliver exceptional strength, corrosion resistance, and longevity. These chains are not merely mechanical links; they represent a sophisticated synergy of metallurgy and precision manufacturing, tailored to excel in the most demanding environments.

The Essence of Stainless Steel Welded Conveyor Chains

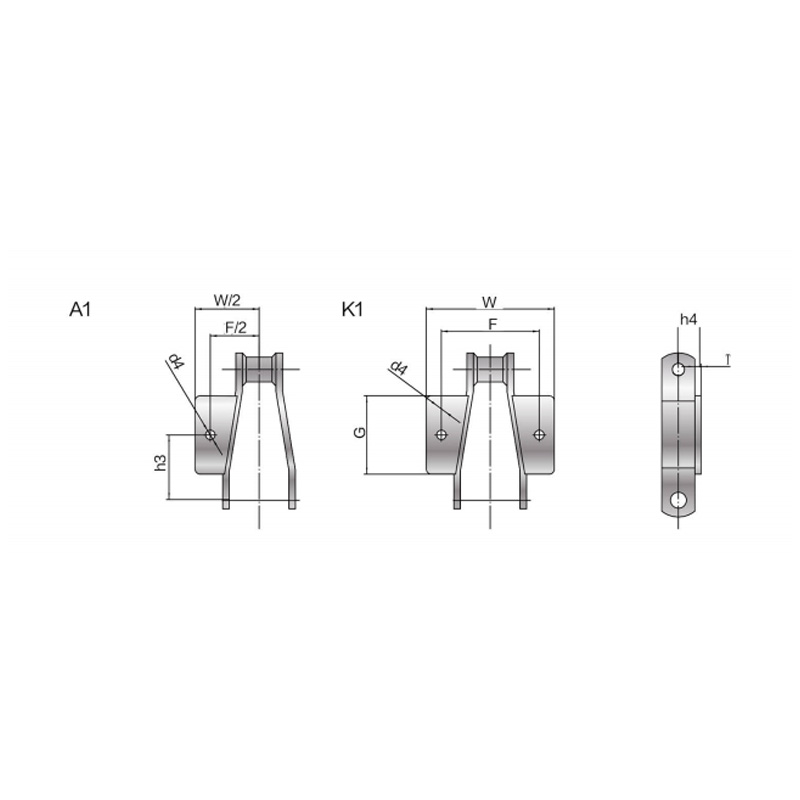

At their core, stainless steel welded conveyor chains consist of individual steel links that are expertly welded to form a continuous, robust loop. Unlike riveted or mechanically assembled chains, the welding process ensures superior joint integrity and tensile strength, significantly reducing the risk of chain failure under heavy loads or high-stress conditions.

The stainless steel material confers exceptional resistance to oxidation, chemicals, and extreme temperatures, making these chains the quintessential choice for industries where hygiene, durability, and environmental resistance are non-negotiable.

Industrial Applications and Performance

Stainless steel welded conveyor chains are ubiquitous across sectors such as food and beverage processing, pharmaceuticals, chemical manufacturing, and marine environments. In food processing plants, for example, these chains withstand rigorous sanitation protocols and exposure to moisture, acids, and alkaline cleaning agents without succumbing to corrosion or fatigue.

The pharmaceutical industry benefits from the non-reactive nature of stainless steel, ensuring contamination-free material transport. Similarly, chemical plants leverage the corrosion-resistant properties of these chains to convey aggressive substances safely and efficiently.

Marine and outdoor applications further underscore the importance of stainless steel. Exposure to saltwater and harsh weather can rapidly degrade conventional carbon steel chains. However, stainless steel’s chromium content forms a passive oxide layer that acts as a shield, preserving the chain’s structural integrity and extending its service life.

Design Advantages of Welded Construction

The welded construction technique imparts several critical advantages. First, it eliminates the weak points inherent in pin-and-rivet designs, delivering enhanced tensile strength and resistance to elongation under load. This is vital for conveyors subjected to continuous heavy-duty operation.

Second, the precision welding process ensures uniformity across the chain’s length, providing consistent pitch and alignment. This uniformity translates to smoother operation, reduced wear on sprockets, and minimized downtime due to maintenance.

Moreover, welded chains can be customized with a variety of attachments and configurations, allowing for tailored solutions that accommodate unique conveyor layouts and material handling requirements.

Material Composition and Grades

Not all stainless steels are created equal. The most prevalent grades used in welded conveyor chains are 304 and 316 stainless steel. Grade 304 is renowned for its excellent corrosion resistance in most environments, good mechanical properties, and affordability. On the other hand, grade 316 incorporates molybdenum, which significantly enhances resistance against chlorides and marine corrosion, making it indispensable for coastal or highly corrosive settings.

The selection between these grades depends on the operational environment and the nature of the materials being conveyed. An astute choice of grade not only optimizes performance but also maximizes return on investment by extending the chain’s operational lifespan.

Maintenance and Longevity

While stainless steel welded conveyor chains are engineered for endurance, prudent maintenance remains critical. Routine inspection for signs of wear, elongation, or surface degradation helps preempt unexpected failures. Lubrication, although less critical for stainless steel than carbon steel chains due to the former’s corrosion resistance, still plays a role in reducing friction and wear, particularly in high-speed or heavily loaded conveyors.

The welded design simplifies maintenance since the chain’s robust structure is less prone to component separation, streamlining replacement and repair processes.

Stainless steel welded conveyor chains epitomize the intersection of strength, resilience, and adaptability. Their superior corrosion resistance, combined with the inherent advantages of welded construction, make them an invaluable asset across a spectrum of industries where operational continuity and product integrity are crucial.

Investing in high-quality stainless steel welded conveyor chains is a strategic decision that mitigates downtime, curtails maintenance costs, and enhances overall production efficiency. In an era where industrial processes demand unwavering reliability, these chains provide the steadfast foundation upon which modern material handling systems are built.