Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsIn the demanding world of material handling, where the margin for error is negligible and downtime costs thousands per hour, every component matters. From the hydraulics to the mast, each part is engineered for peak performance and relentless durability. Yet, one component often works silently in the background, bearing immense loads with every lift, lower, and reach: the leaf chain.

While often overshadowed by more complex systems, the leaf chain is a masterpiece of mechanical simplicity and brute strength. It is the unsung hero of load-bearing motion, the critical link between power and performance. For engineers, maintenance managers, and procurement specialists in the forklift and hoist industries, specifying the right chain isn’t just a detail—it’s a fundamental decision that impacts safety, productivity, and total cost of ownership.

To appreciate why leaf chains excel, we must first understand what they are. Often confused with roller chain, a leaf chain assembly has a distinct and purpose-built design.

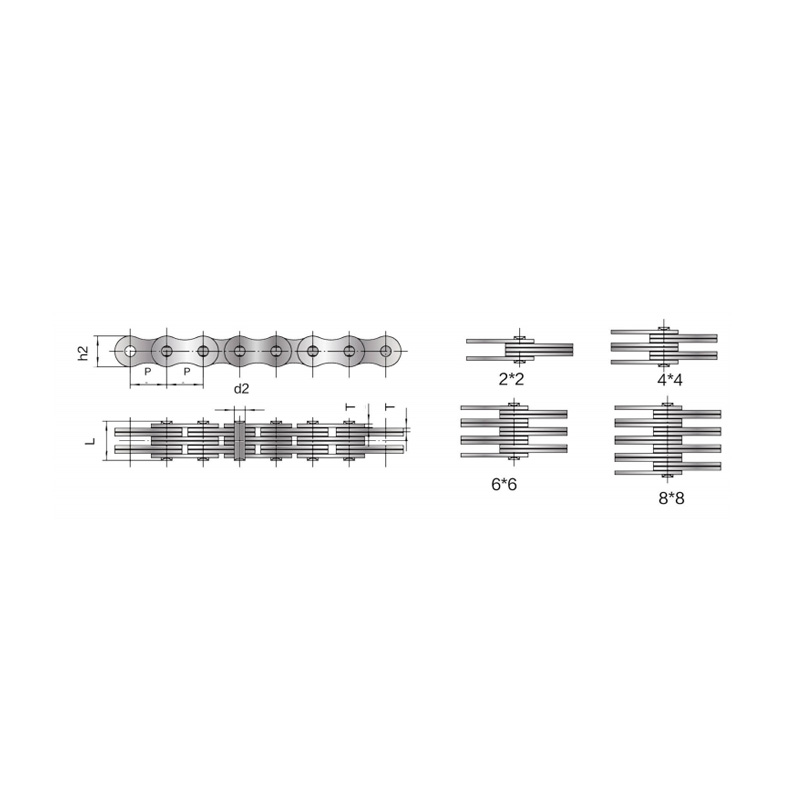

A leaf chain is constructed from a series of stacked, flat, parallel side plates—or “leaves”—pinned together by solid, precision-ground pins. Unlike roller chain, it has no rollers or bushings. This simple structure consists of two main components:

Link Plates (Leaves): These are the high-tensile steel plates that are stacked together. Their overlapping design creates an incredibly robust, yet flexible, assembly.

Pins: Hardened steel pins hold the link plates together, allowing for articulation under load.

This heavy-duty leaf chain design results in a narrow, high-strength assembly that is perfectly suited for load-leveling applications where the chain operates over sheaves or sprockets, transmitting force in a straight line with minimal side-to-side movement.

The unique construction of leaf chains provides a suite of benefits that directly address the challenges faced by forklifts and hoists.

The primary reason for the dominance of leaf chains is their exceptional strength-to-width ratio. By stacking multiple plates, the load is distributed evenly across a wide area of each pin and plate. This design allows a relatively narrow chain to handle immense tensile forces.

In a forklift, this translates to the ability to lift multi-ton loads to significant heights without fear of chain elongation or catastrophic failure.

In a hoist, it means reliable, safe vertical lifting where the chain is the sole component suspending the load.

This makes them ideal for high-capacity lifting equipment where space is constrained but demands are extreme.

For chain specialists, “elongation” is a key metric. It refers to the permanent stretching of a chain under load over time, primarily caused by wear at the pin and bushing joints. Excessive elongation is dangerous, as it alters the equipment’s geometry and can lead to failure.

Leaf chains are renowned for their low elongation characteristics. The solid pin-to-plate contact area is large, distributing wear evenly and slowing the process of elongation. This provides a longer service life where precise positioning is maintained. For a forklift operator, this means consistent fork height control. For a hoist operator, it means predictable and safe lifting without unexpected “chain stretch.”

Forklift and hoist chains operate in harsh environments. They are exposed to dust, grit, metal shavings, and extreme temperature variations. The simplicity of the leaf chain is its armor.

The hardened steel pins and high-quality alloy steel plates offer tremendous abrasion resistance for industrial chains. The lack of small, intricate parts like rollers means there are fewer cavities for abrasive contaminants to become trapped and accelerate wear. This robust construction ensures reliability in demanding warehouse applications and rugged outdoor yards alike.

While incredibly strong in tension, a leaf chain must also be flexible to bend smoothly over sheaves. The multiple, thin plate design allows for a tight bend radius without inducing high stress concentrations. This flexibility contributes to:

Smooth engagement with sprockets, reducing noise and vibration.

Reduced wear on the chain itself and the sheaves it runs over.

Consistent, jerk-free lifting and lowering, which is crucial for both load stability and operator confidence.

Ultimately, every advantage of a leaf chain culminates in one critical benefit: safety. The robust construction for forklift chains is engineered with failure prevention as a core principle. Their high strength and low elongation provide a significant safety factor, far exceeding the rated loads they are designed to handle.

Industry standards, such as the National Association of Chain Manufacturers (NACM) standards in the US, govern the manufacture and testing of leaf chains. Reputable manufacturers subject their chains to rigorous proof testing, ensuring each chain can withstand loads well beyond its working limit before it ever leaves the factory. This built-in reliability is non-negotiable for overhead lifting equipment and load-bearing machinery.

In a forklift, the leaf chain is the backbone of the mast’s lifting mechanism. It is typically anchored to the carriage and routed over sheaves at the top of the mast. When the hydraulic cylinder extends, it pulls on the chain, lifting the carriage and its load.

Here, the forklift mast chain requirements are exacting:

Precise Length: Minimal elongation is critical to maintain synchronized fork movement and accurate height control.

Compact Design: The chain must fit within the narrow confines of the mast channels.

Shock Load Resistance: Forklifts are subject to dynamic loading—sudden stops, starts, and uneven surfaces. The leaf chain’s robust design absorbs these shocks effectively.

Using an inferior chain can lead to mast chatter, uneven lifting, and ultimately, a catastrophic chain failure that could drop a load.

In lever hoists, chain hoists, and winches, the leaf chain is both the lifting and load-holding element. It is wound onto a load wheel and is directly handled by the operator.

Hoist chain specifications demand even more:

The clean, smooth profile of a leaf chain is also easier and safer to grip than a roller chain, reducing hand fatigue and improving operator control.

Choosing the right leaf chain is not a one-size-fits-all process. Key leaf chain selection criteria include:

Working Load Limit (WLL): The maximum load the chain is designed to handle under normal service conditions. Never exceed the WLL.

Grade of Material: Chains are made from various grades of alloy steel (e.g., Grade 80, Grade 100, Grade 120). Higher grades offer greater strength for a given size but may have different flexibility characteristics.

Attachments: Custom hooks, clevises, or other attachments can be specified for direct connection to equipment.

Manufacturer Reputation: Source chains from reputable manufacturers who adhere to NACM or other international standards (e.g., ISO).

Even the best chain will fail prematurely without proper care. Leaf chain maintenance tips are straightforward but vital:

Lubrication: Regular lubrication with a suitable chain lubricant reduces internal friction, minimizes wear, and protects against corrosion.

Inspection: Conduct regular inspections for signs of wear, including nicks, gouges, cracks, or visible elongation. The “go/no-go” gauge method is a common and effective way to check for wear.

Cleanliness: Keep chains as clean as possible to prevent abrasive particles from accelerating wear.

Proper Storage: Spare chains should be stored in a dry, clean environment to prevent rust before they are even put into service.

Understanding the causes of leaf chain failure—most commonly wear-induced elongation, improper lubrication, overload, or material defects—is the first step in prevention.

While the initial purchase price is a factor, the true cost of a chain is calculated over its entire service life. This is where leaf chains truly shine and justify their position as the first choice.

Longer Service Life: Their durability and low elongation mean fewer replacements. This reduces direct parts costs and the labor required for change-outs.

Reduced Downtime: A failed chain halts an entire operation. The reliability of a quality leaf chain maximizes uptime, keeping goods moving and projects on schedule.

Safety Cost Avoidance: The cost of a chain failure is not just a new chain. It can include damaged loads, damaged equipment, workplace injuries, and regulatory fines. Investing in a proven, reliable component is a cheap insurance policy.

This focus on maximizing chain service life and minimizing downtime in material handling makes the leaf chain an economically superior choice in the long run.

In the high-stakes environment of material handling, compromise is not an option. The leaf chain, with its elegant simplicity, unparalleled strength, and proven reliability, remains the foundational component for safe and efficient lifting.

Its design, perfected over decades, is a direct response to the brutal demands of forklifts and hoists. By choosing a high-quality leaf chain from a reputable manufacturer, and pairing it with a diligent maintenance program, you are not just selecting a component—you are investing in the safety of your personnel, the protection of your assets, and the uninterrupted productivity of your operation. It is a choice that, quite literally, holds everything up.