Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsChemical wastewater management has become one of the most pressing environmental and industrial challenges of modern times. With rapid industrialization and increasing production in sectors such as petrochemicals, pharmaceuticals, and metallurgy, large volumes of wastewater containing hazardous chemicals are discharged daily. To prevent pollution and protect public health, treatment facilities must use robust and reliable equipment designed to withstand aggressive environments. Among the many components of wastewater systems, the sewage treatment chain plays a crucial role. It is responsible for driving mechanical processes such as sludge removal, water transfer, and the operation of settling tanks.

In chemical wastewater environments, equipment is exposed to conditions that are far more severe than those in municipal water treatment. High concentrations of corrosive chemicals, abrasive particles, and fluctuating loads require specialized solutions. The sewage treatment chain, when engineered with appropriate materials and surface treatments, provides the strength, wear resistance, and corrosion protection needed to maintain efficiency and safety in these facilities.

A sewage treatment chain is a mechanical transmission component that is commonly used in sedimentation tanks, sludge collection systems, and water transfer equipment. It connects different elements of the treatment system, transmitting motion and enabling the continuous removal and transport of sludge or other solids.

In a municipal setting, the chain may operate under moderate conditions, handling biological sludge and organic matter. However, in chemical wastewater treatment facilities, the situation is significantly more demanding. Chains must endure high concentrations of acids, alkalis, solvents, and suspended solids that can quickly degrade ordinary materials. Without proper design, chains would fail prematurely, leading to operational downtime and higher maintenance costs.

By ensuring reliable motion transfer and consistent removal of waste materials, sewage treatment chains act as the hidden backbone of chemical wastewater plants. They enable systems to function without interruption, supporting the broader goal of environmental compliance and public safety.

Chemical wastewater often contains acids, alkalis, and salts in high concentrations. These substances can corrode ordinary steel chains, weakening their structure and reducing lifespan. Corrosion also leads to contamination risks if metal fragments enter the treated water stream.

Solid particles such as sand, metal shavings, or chemical residues are frequently present in wastewater. As chains move continuously, these particles grind against surfaces, causing significant wear and tear. Without high wear resistance, chains would require frequent replacement.

Wastewater plants experience fluctuating loads, especially during peak production hours in industrial facilities. Chains must withstand both steady operation and sudden torque increases without breaking or stretching.

Some chemical wastewater processes involve elevated temperatures, either due to reactions or thermal discharges. High heat can reduce the strength of standard materials and accelerate chemical attack.

Failure of chains in chemical wastewater plants can lead not only to downtime but also to safety hazards and environmental violations. Chains must therefore be designed with a high degree of reliability to meet regulatory standards.

Material choice is the first line of defense against chemical wastewater challenges. The most commonly used materials include:

Special alloy steel: Provides high strength and toughness, suitable for heavy loads. However, without surface protection, it may be vulnerable to corrosion.

Special stainless steel: Offers a balance between strength and corrosion resistance, making it particularly suitable for environments containing acids and alkalis. Grades such as austenitic stainless steel are often selected for their superior resistance.

Hardened steels with coatings: In some cases, carbon or alloy steels are treated with protective coatings that enhance corrosion and wear resistance.

By selecting the right material, engineers ensure that chains can withstand both the mechanical and chemical stresses of wastewater systems.

Even the best materials may struggle against the extreme conditions of chemical wastewater. To improve durability, manufacturers apply advanced surface treatments and strengthening processes, such as:

Heat treatment: Increases hardness and wear resistance, reducing material loss during abrasion.

Surface hardening: Improves the outer layer of the chain while maintaining core toughness.

Anti-corrosion coatings: Thin protective films act as barriers against acids, alkalis, and chlorides.

Passivation of stainless steel: Enhances natural oxide layers, improving resistance to chemical attack.

These treatments extend the operational life of chains, reduce maintenance frequency, and minimize downtime.

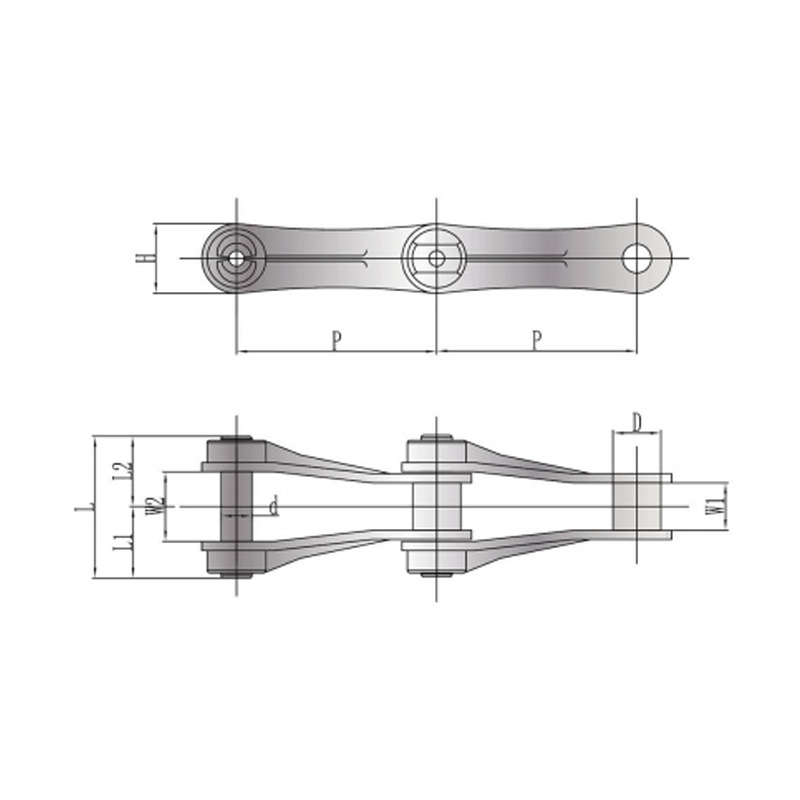

The geometry and engineering of chains are as important as the material itself. Several design considerations help improve performance in harsh environments:

Robust link construction: Stronger links ensure that sudden load increases do not lead to failure.

Smooth surface finishes: Reduce the risk of chemical deposits and make cleaning easier.

Optimized pitch and thickness: Provide stability during heavy-duty operation.

Tight tolerances: Prevent unnecessary movement that can accelerate wear.

Sealed joints and pins: Reduce the entry of abrasive particles and corrosive liquids into chain interiors.

Through thoughtful design, sewage treatment chains achieve both mechanical efficiency and environmental resistance.

Even with the best materials and treatments, sewage treatment chains require careful maintenance to ensure long service life. Recommended practices include:

Regular inspection: Checking for signs of wear, corrosion, or elongation helps detect issues early.

Lubrication: Specialized lubricants protect against friction and chemical attack. In some cases, dry-film coatings are used to avoid contamination.

Cleaning procedures: Removing chemical residues and solid deposits reduces abrasive wear.

Replacement scheduling: Predictive maintenance ensures chains are replaced before failure occurs, avoiding costly downtime.

When operators follow these practices, chains can remain reliable components of chemical wastewater treatment for many years.

Municipal-industrial combined plants

In large cities where municipal and industrial wastewater streams merge, sewage treatment chains must handle mixed loads that include both biological and chemical contaminants. Stainless steel chains with protective coatings are often employed in such facilities.

Petrochemical wastewater facilities

Petrochemical plants discharge wastewater with high levels of hydrocarbons, solvents, and acids. Chains in these environments are typically surface-hardened and corrosion-resistant, ensuring stable operation despite constant exposure to aggressive compounds.

Pharmaceutical wastewater treatment

The pharmaceutical sector produces effluents containing solvents, biological residues, and reactive agents. Chains used here require precise engineering to withstand not only corrosion but also strict regulatory standards.

Heavy metal wastewater plants

In facilities that process electroplating or mining effluents, wastewater often contains high concentrations of heavy metals. Chains must resist both chemical corrosion and abrasive wear caused by suspended particles.

Using high-performance sewage treatment chains in chemical wastewater environments offers several advantages:

Reduced maintenance costs: Durable chains require fewer replacements and repairs.

Improved plant efficiency: Reliable operation supports continuous wastewater treatment without interruptions.

Extended equipment lifespan: Chains that resist corrosion and wear contribute to the longevity of entire systems.

Environmental protection: By ensuring consistent wastewater treatment, chains help facilities meet environmental regulations and protect ecosystems.

These benefits highlight the importance of investing in quality chains tailored to the specific challenges of chemical wastewater.

As industries evolve, wastewater treatment technologies continue to advance. Future trends in sewage treatment chains may include:

Smart monitoring systems: Sensors embedded in chains could provide real-time data on wear and load, supporting predictive maintenance.

Advanced composite materials: Hybrid chains incorporating non-metallic components may enhance resistance to both corrosion and abrasion.

Eco-friendly coatings: Development of surface treatments with lower environmental impact could improve sustainability.

Customization for specific industries: Chains may be engineered for niche applications, such as semiconductor wastewater or biotechnology effluents.

These innovations promise to further strengthen the role of sewage treatment chains in addressing complex wastewater challenges.

Chemical wastewater environments demand equipment that can withstand corrosion, abrasion, temperature fluctuations, and heavy loads. The sewage treatment chain, when manufactured from high-quality materials and enhanced with specialized treatments, provides the strength, durability, and resistance necessary to function under these extreme conditions. By enabling reliable operation of sludge tanks, transfer systems, and other wastewater equipment, chains support both environmental protection and industrial productivity.

Through careful material selection, advanced surface treatments, thoughtful design, and proper maintenance, sewage treatment chains continue to prove their value as indispensable components in chemical wastewater treatment facilities. As industries grow and environmental standards become more stringent, the evolution of chain technology will remain a vital part of sustainable water management.