Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsIn the food industry, efficiency and reliability are crucial factors in maintaining high production standards. Processing lines, whether for baking, freezing, packaging, or general food preparation, depend heavily on the performance of machinery components. One of the most critical components in these systems is the chain. Food machinery industry chains are designed to transmit power, move products, and synchronize operations across various types of equipment. When properly selected and maintained, these chains can significantly enhance the efficiency of food processing lines.

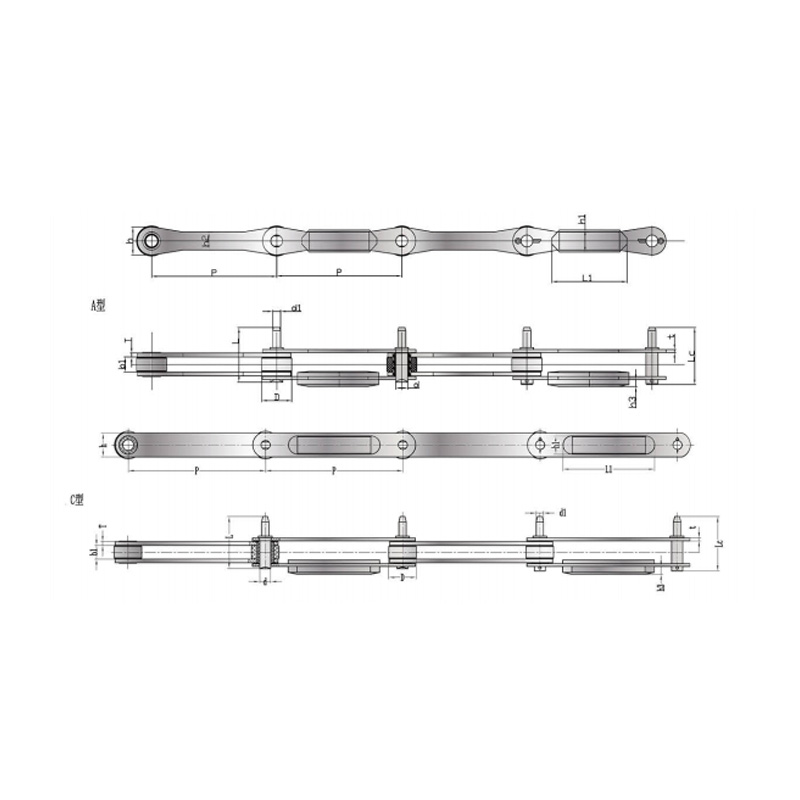

Chains in food machinery serve multiple purposes. They are responsible for driving conveyors, mixers, slicers, and packaging equipment. Unlike standard industrial chains, those used in food processing must meet additional requirements, including resistance to corrosion, ability to withstand repeated cleaning, and suitability for contact with food products. By ensuring smooth and reliable motion across processing lines, chains directly affect the speed, consistency, and quality of production.

One of the main ways to improve efficiency in processing lines is through careful material selection. Chains in food machinery are typically made from stainless steel or other corrosion-resistant alloys. Stainless steel is favored for its durability and ability to withstand harsh cleaning chemicals and high-moisture environments. In some cases, special coatings or surface treatments are applied to further enhance wear resistance and reduce friction. Selecting the right material ensures the chain operates smoothly over long periods without frequent replacement, minimizing downtime.

Food machinery chains are designed with specific operational requirements in mind. For example, chains in high-speed bakery lines must allow precise synchronization between dough rollers, conveyors, and cutters. In freezing operations, chains need to endure extremely low temperatures while maintaining flexibility and strength. Packaging lines often require chains that can handle sudden changes in load without stretching or breaking. Proper design reduces energy consumption, prevents mechanical failures, and ensures consistent product flow.

Downtime is one of the most significant challenges in food processing. When a chain fails or requires frequent adjustment, production lines come to a halt, affecting both output and revenue. High-quality food machinery chains improve efficiency by minimizing maintenance requirements. Chains manufactured with wear-resistant materials, hardened pins, and reinforced links can operate for extended periods without failure. Routine maintenance, such as lubrication and inspection, further extends service life, keeping lines running smoothly.

Efficiency in food processing lines is not only about speed but also about maintaining hygiene and safety standards. Chains in contact with food must be easy to clean and resistant to contamination. Many food machinery chains feature open link designs or smooth surfaces that prevent accumulation of debris. Corrosion-resistant materials ensure that cleaning agents do not degrade the chain, maintaining both performance and food safety compliance. Efficient cleaning processes reduce the time machines are offline, contributing to overall productivity.

Food processing environments vary widely. Chains must be adapted to specific conditions such as high humidity, exposure to oils or acids, temperature extremes, and heavy product loads. Specialized chains are available for freezing tunnels, dough processing, meat and poultry lines, and beverage bottling. By selecting chains suited to these conditions, manufacturers can prevent premature wear, reduce energy loss, and maintain consistent line speed. This adaptation directly impacts the overall efficiency of the processing line.

Friction in chain systems can lead to increased energy consumption and wear. Modern food machinery chains are designed to minimize friction through precise engineering and the use of self-lubricating materials or coatings. Reduced friction not only lowers energy requirements but also decreases heat generation and the risk of mechanical failure. Efficient chains transfer power effectively from motors to equipment, ensuring smooth operation and optimized production output.

Automation is increasingly important in food processing lines. Chains play a vital role in enabling automated movement of products and machinery components. Accurate and reliable chain operation is essential for synchronizing automated processes such as sorting, filling, and packaging. Misalignment or inconsistent chain performance can lead to product damage, delays, or line stoppages. Using chains engineered for high precision enhances the reliability of automated systems and improves overall line efficiency.

Even the best-designed chains require proper maintenance to maximize efficiency. Regular inspection for wear, elongation, or damage is crucial. Lubrication, when appropriate, reduces friction and extends chain life. In some food processing applications, chains must be cleaned frequently to prevent contamination. Implementing a systematic maintenance schedule ensures that chains remain in optimal condition, reducing unexpected downtime and maintaining consistent line speeds.

Several examples demonstrate how selecting the right chains can improve processing line efficiency. In bakery operations, switching to corrosion-resistant, wear-proof chains reduced line stoppages and improved throughput. In frozen food facilities, specialized chains designed to operate at low temperatures maintained conveyor speed and minimized energy consumption. Packaging plants using chains with precise tolerances achieved better synchronization between filling, capping, and labeling processes. These cases highlight the importance of chain selection and maintenance in achieving operational efficiency.

Food machinery industry chains are integral to the performance and efficiency of processing lines. Proper selection of materials, careful attention to design, and regular maintenance can reduce downtime, improve product flow, and ensure hygiene compliance. Chains that are corrosion-resistant, wear-resistant, and adapted to specific working conditions help manufacturers achieve consistent, high-speed operations while minimizing energy use and mechanical failures. By understanding the role of chains and implementing best practices, food processing facilities can optimize efficiency, reduce costs, and maintain high standards of production quality.