Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsDriving chain are essential components in machinery, motorcycles, bicycles, and industrial equipment. This guide covers everything you need to know about driving chains, including types, maintenance tips, and troubleshooting common issues.

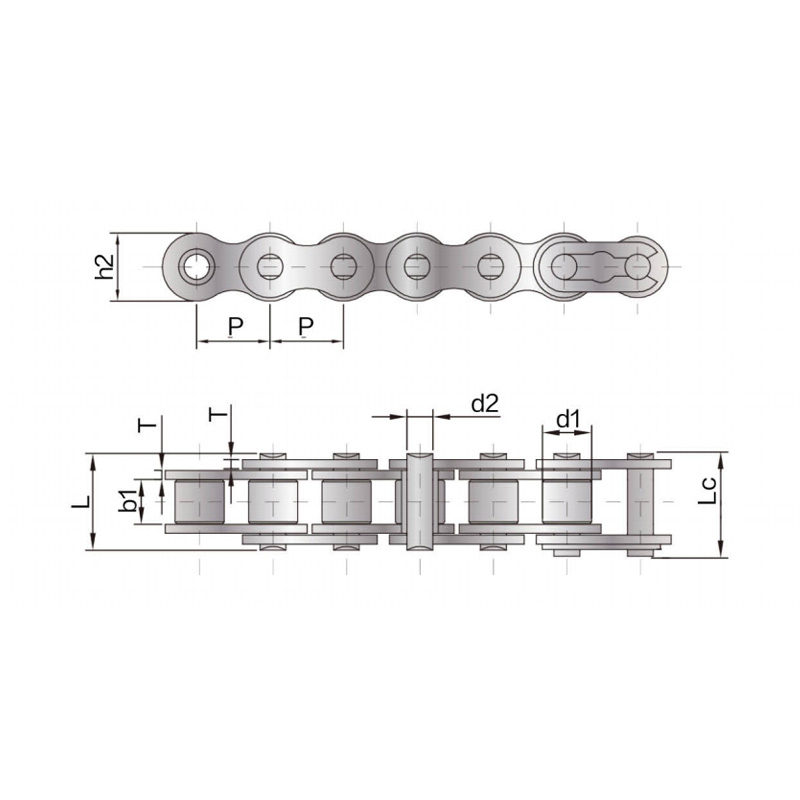

A driving chain is a series of interconnected links that transmit mechanical power from one component to another. It is commonly used in vehicles, conveyor systems, and industrial machinery.

Different applications require specific types of chains. Below is a comparison of the most common types:

| Type | Description | Common Uses |

| Roller Chain | Features cylindrical rollers for smooth engagement with sprockets. | Bicycles, motorcycles, industrial machinery. |

| Silent Chain | Operates quietly with inverted tooth design. | Automotive timing systems, high-speed drives. |

| Leaf Chain | Consists of stacked plates for high tensile strength. | Forklifts, lifting equipment. |

| Conveyor Chain | Designed for material transport in production lines. | Manufacturing, packaging. |

Proper maintenance extends the lifespan of a driving chain. Follow these steps:

| Problem | Cause | Solution |

| Chain Slippage | Loose tension or worn sprockets. | Adjust tension or replace sprockets. |

| Excessive Noise | Lack of lubrication or misalignment. | Lubricate or realign the chain. |

| Rust Formation | Exposure to moisture without protection. | Clean and apply anti-rust coating. |

| Chain Stretching | Normal wear over time. | Replace the chain if elongation exceeds limits. |

Signs that indicate a chain needs replacement:

A well-maintained driving chain ensures efficient power transmission and reduces downtime. By understanding the types, performing regular maintenance, and addressing problems early, you can maximize the performance and lifespan of your chain.