Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

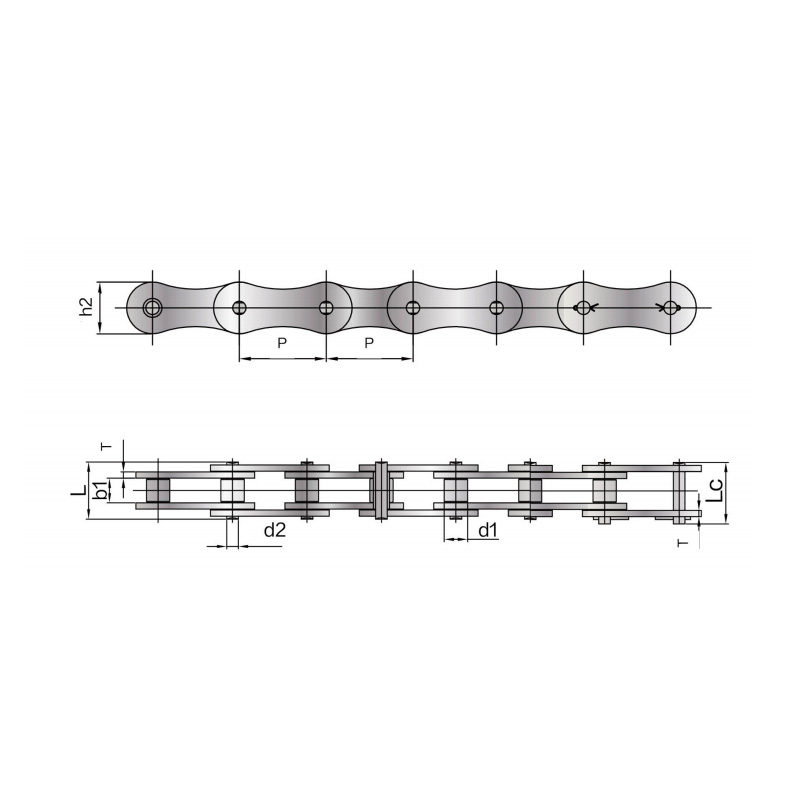

See DetailsLeaf chain is crucial components in various industrial applications, known for their strength and durability. Unlike standard roller chains, leaf chains are designed specifically for linear motion and heavy load-bearing applications. This comprehensive guide covers everything you need to know about leaf chains, including their construction, types, specifications, and maintenance.

Leaf chains consist of multiple link plates (or leaves) assembled in parallel rows with pins. This unique construction provides several advantages:

The alternating pattern of pin links and roller links distributes weight evenly across multiple plates, making leaf chains ideal for applications where standard chains would fail.

Leaf chains serve critical functions across multiple industries:

| Industry | Application | Benefits |

|---|---|---|

| Material Handling | Forklift masts, lift trucks | High vertical load capacity |

| Construction | Cranes, hoists, elevators | Durability in dirty environments |

| Agriculture | Harvesters, balers | Resistance to shock loads |

| Manufacturing | Conveyor systems, presses | Precise linear motion |

Leaf chains are categorized based on their construction and performance characteristics:

These are the most common type, featuring alternating pin and roller links. They offer excellent load capacity and are suitable for most general applications.

Designed for extreme conditions, these chains have:

These chains feature special coatings or materials for use in:

Leaf chains are available in various sizes and configurations. Key specifications include:

| Chain Size | Pitch (mm) | Roller Width (mm) | Minimum Tensile Strength (kN) |

|---|---|---|---|

| LH0822 | 12.7 | 7.4 | 31.1 |

| LH0823 | 12.7 | 11.1 | 44.5 |

| LH1222 | 15.875 | 7.4 | 44.5 |

| LH1223 | 15.875 | 11.1 | 66.7 |

| LH1623 | 19.05 | 11.1 | 88.9 |

Note: Actual working load limits are typically 1/6 to 1/10 of the minimum tensile strength for safety.

Choosing the appropriate leaf chain involves considering several factors:

Calculate both:

Consider exposure to:

Higher speeds may require:

Proper installation and maintenance significantly extend leaf chain life:

| Environment | Lubrication Type | Frequency |

|---|---|---|

| Normal conditions | SAE 30-50 oil | Every 8 hours |

| High temperature | High-temperature grease | Every 4 hours |

| Wet conditions | Water-resistant grease | Every shift |

| Food grade | NSF H1 lubricants | As specified |

Regular inspections should check for:

Understanding typical leaf chain issues helps prevent downtime:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Excessive wear | Improper lubrication, misalignment | Adjust alignment, increase lubrication |

| Chain stretch | Overloading, worn components | Replace chain, reduce load |

| Corrosion | Moisture exposure, improper chain type | Use corrosion-resistant chain, improve sealing |

| Noisy operation | Dry joints, worn components | Lubricate, inspect for wear |

Working with leaf chains requires attention to safety:

Service life varies based on:

While individual components can sometimes be replaced, most experts recommend complete chain replacement for critical applications to ensure uniform strength.

Measure multiple pitches and compare to new chain specifications. More than 3% elongation typically indicates replacement is needed.

Leaf chains are essential components in many industrial applications, offering superior strength and durability for linear motion systems. By understanding their types, specifications, and proper maintenance requirements, you can ensure optimal performance and longevity. Regular inspection and proper lubrication are key to maximizing service life while maintaining safety. Always consult technical specifications and safety guidelines when selecting and maintaining leaf chains for your specific application.