Fubang is a professional manufacturer specializing in the design, production and sales of stainless steel chains.

Our A series short pitch precision roller chains comply with various international standards and are...

See DetailsConveyor chain is the backbone of material handling systems across numerous industries. Selecting the right chain can dramatically impact your operation's efficiency, maintenance costs, and productivity. This comprehensive guide covers everything from chain types and materials to maintenance best practices and troubleshooting common issues.

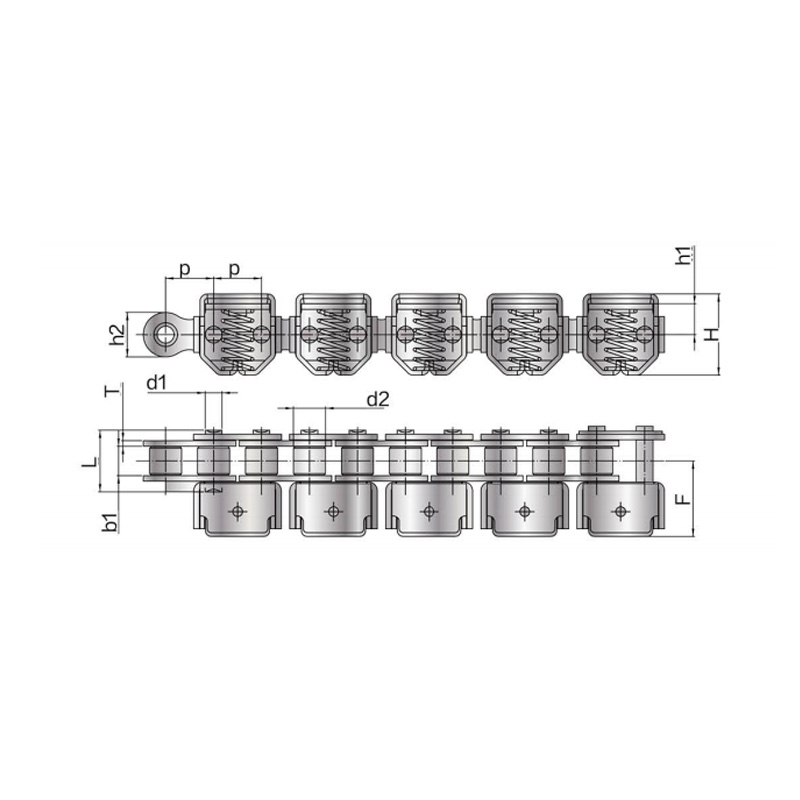

Conveyor chains are continuous chains used to move materials in manufacturing and processing facilities. They consist of interconnected links that engage with sprockets to create smooth material movement. Key components include:

| Chain Type | Description | Common Applications |

| Roller Chains | Most common type with cylindrical rollers | General material handling, packaging lines |

| Silent Chains | Operates quietly with inverted tooth design | Food processing, printing presses |

| Flat Top Chains | Flat surface for product conveyance | Bottling plants, automotive assembly |

| Magnetic Chains | Contains magnets for ferrous materials | Scrap metal handling, recycling |

| Side Flexing Chains | Can navigate curves in conveyor system | Distribution centers, warehousing |

Choosing the right conveyor chain requires careful consideration of multiple factors:

Calculate both static and dynamic loads your chain will experience. Include impact loads from starting/stopping and potential overload scenarios.

Consider temperature extremes, moisture, chemical exposure, and abrasive conditions that could affect chain performance.

Higher speeds require chains with precision components. Continuous operation demands more durable materials than intermittent use.

Hard-to-reach installations may need chains with extended service life or special lubrication features.

| Material | Advantages | Limitations | Best For |

| Carbon Steel | High strength, cost-effective | Prone to rust, needs lubrication | General industrial use |

| Stainless Steel | Corrosion resistant, hygienic | Higher cost, lower strength | Food, chemical, marine |

| Nickel Plated | Good corrosion resistance | Coating can wear off | Moderate corrosive environments |

| Plastic/Nylon | Lightweight, quiet operation | Lower load capacity | Light-duty, clean rooms |

Effective lubrication extends chain life by reducing wear between moving parts. Common methods include:

| Operating Conditions | Recommended Interval |

| Clean, moderate speed (under 500 fpm) | Every 8 hours |

| High speed (500-1500 fpm) | Continuous lubrication |

| Dirty or abrasive environment | Every 4 hours |

| High temperature operation | Every 4 hours with high-temp grease |

Causes: Improper lubrication, misalignment, overload

Solutions: Adjust lubrication schedule, check alignment, verify load capacity

Causes: Normal wear, excessive loads

Solutions: Regular measurement, replace when elongation exceeds 3%

Causes: Lack of lubrication, worn components

Solutions: Lubricate properly, inspect and replace worn parts

Causes: Moisture exposure, improper material selection

Solutions: Use stainless steel or coated chains, improve environment

Implementing a regular maintenance program can prevent costly downtime:

Chain service life depends on multiple factors. Use this simplified formula for estimation:

Chain Life (hours) = (K × L) / (T × S × F)

Where:

K = Material constant (5000 for steel)

L = Lubrication factor (1 for proper, 0.5 for poor)

T = Tension factor (1 for proper, 2 for high)

S = Speed factor (1 for <500 fpm, 1.5 for >500 fpm)

F = Environment factor (1 for clean, 3 for abrasive)

Always follow these safety guidelines when working with conveyor chains:

Watch for these signs indicating needed replacement:

The conveyor chain industry continues to evolve with these emerging developments:

Selecting and maintaining the right conveyor chain requires understanding your specific application needs, operating conditions, and maintenance capabilities. By following the guidelines in this article, you can optimize your conveyor system's performance, extend component life, and reduce unexpected downtime. Regular inspection and proper lubrication remain the most effective strategies for maximizing your conveyor chain investment.