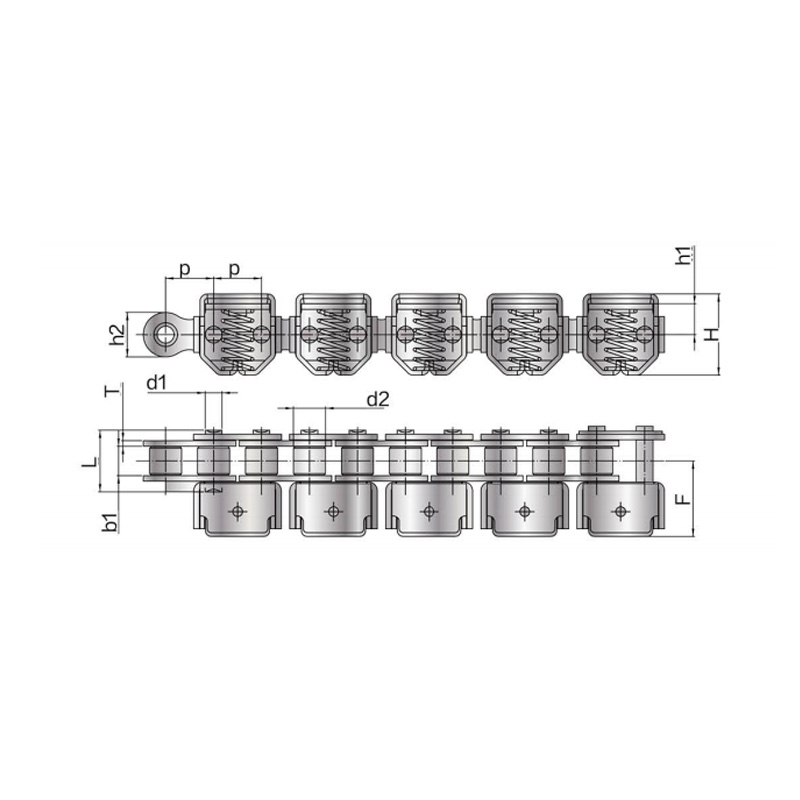

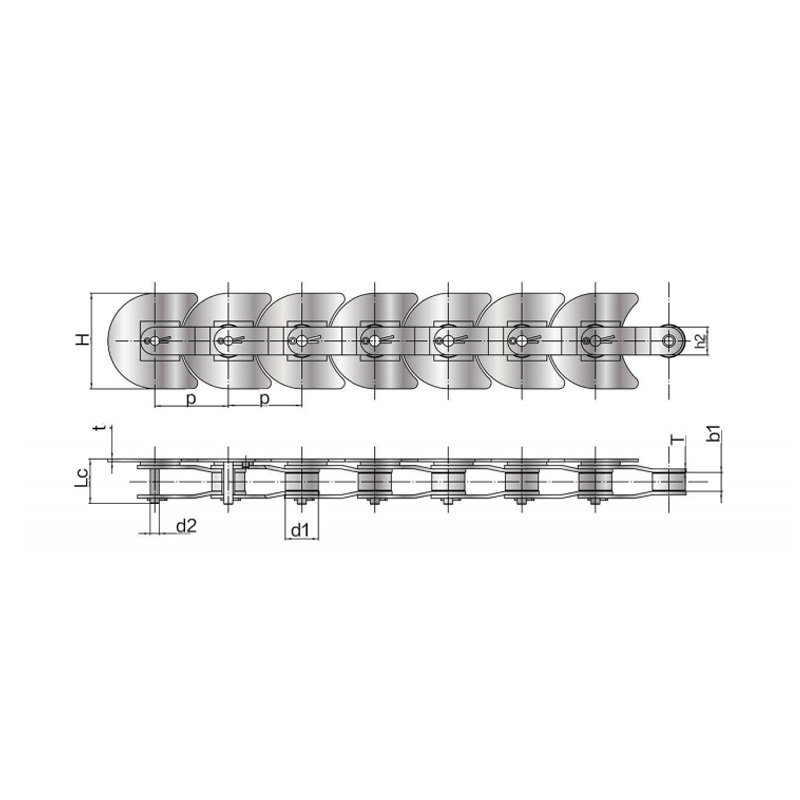

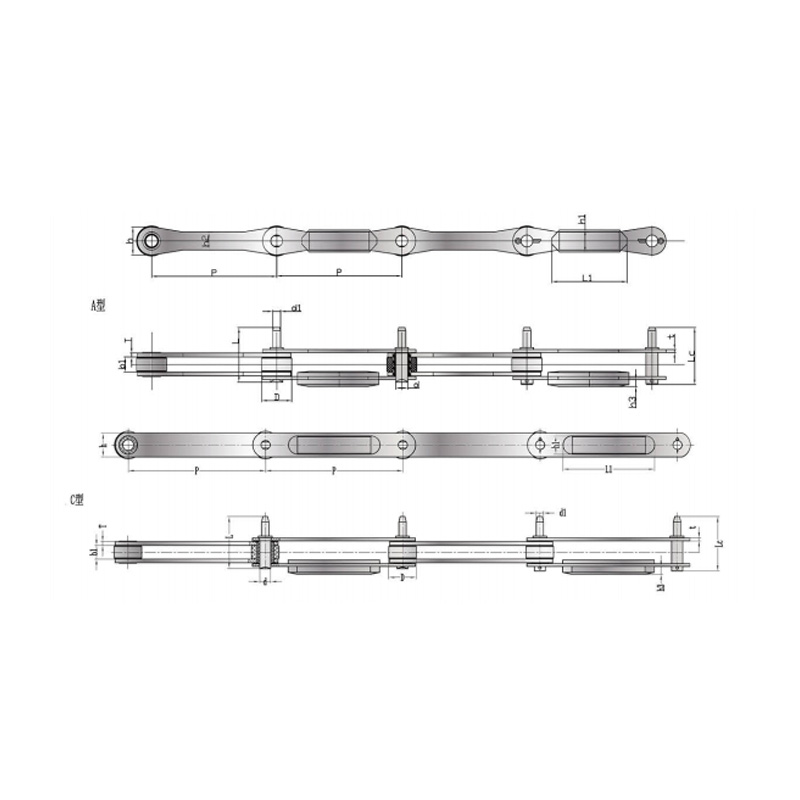

This conveyor chain realizes material transportation based on the clamping and conveying principle. ...

Food Machinery Industry Chains Manufacturers

Our chain for food machinery can be used in various types of food processing, freezing, baking, packaging and other equipment. According to different working conditions, appropriate materials and special processes are selected to improve corrosion resistance and wear resistance and can meet the use requirements of various types of equipment.

-

-

Sushi Conveyor Chain

Sushi Conveyor ChainThis stainless steel conveyor chain is mainly used for conveying sushi and is used in conveyor belt ...

-

Ice cream machine Chain

Ice cream machine ChainUsed in ice cream processing production lines, it has the characteristics of wear resistance, corros...

-

Stored Frozen Food Conveyor Chain

Stored Frozen Food Conveyor ChainThis Stored Frozen Food Conveyor Chain is mainly used in frozen food production equipment in rotatin...

-

Hot dog production line conveyor Chain

Hot dog production line conveyor ChainThe stainless steel sausage production line conveyor chain can complete the automatic transportation...

-

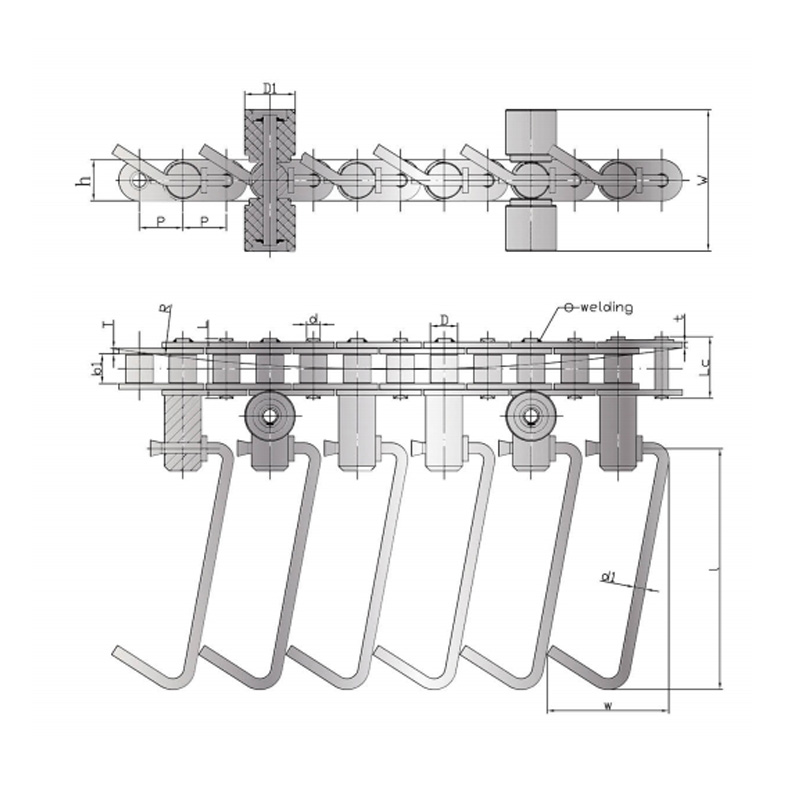

Food machinery Hoof Chain

Food machinery Hoof ChainThis Chain is widely used in food freezing equipment. It uses left and right horseshoe-shaped chain ...

-

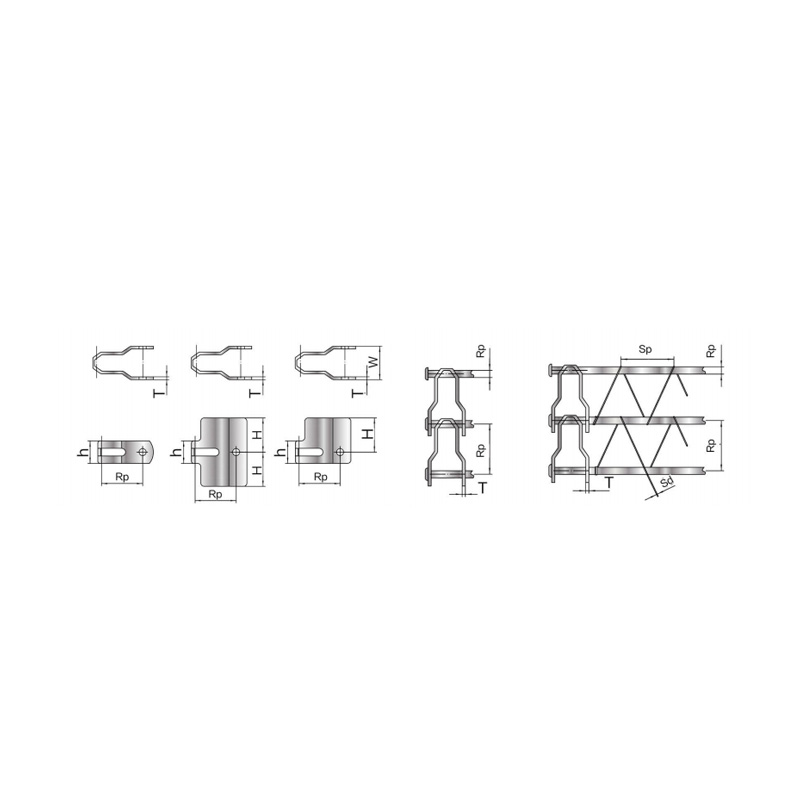

Food machinery Rod reinforced Wire Conveyor Belt

Food machinery Rod reinforced Wire Conveyor BeltFlat wire mesh belt, this Food machinery Rod reinforced belt is made of rolled flat wire and connect...

-

Food machinery Flat Wire Conveyor Belt

Food machinery Flat Wire Conveyor BeltFood machinery Flat wire belt, also known as Great Wall mesh belt, is made of metal plate and belt m...

-

Food machinery Wire ring belt

Food machinery Wire ring beltCoil-type mesh belt, also known as glasses mesh belt, is a single-layer conveyor belt. It is often m...

-

Food machinery Chain driven Wire Conveyor Belt

Food machinery Chain driven Wire Conveyor BeltThe chain mesh belt is mainly made up of chains on the left and right sides and a middle mesh belt c...

After years of unremitting efforts, as Custom Food Machinery Industry Chains Manufacturers in China, Fubang's R&D team has achieved a number of technological achievements in the field of chain manufacturing, ensuring the integrity of the company's technical processes and the diversity of its products, and forming a deep technical reserve.

Suzhou Fubang Machinery Chain Transmission Manufacturing Co,. Ltd, or Fubang for short, was established in 2018. We developed from Suzhou Fulong Stainless Steel Chain Factory in 1997. Now we are located at No.6 Shengtai Road, Xiangcheng District, Suzhou, with a factory area of 18,000 square metres. After 25 years of development, we have become a professional manufacturer specialising in design, production and sale of stainless steel chains. Food Machinery Industry Chains Manufacturers.

We have set up an R&D cooperation center with Jiangnan University. Now Fubang is a member of the National Chain Transmission Standardization Technology Committee China General Parts Industry Association and National High Technology Enterprise. As Food Machinery Industry Chains Factory, we have been awarded Certificate of ISO9001:2015 and GB/T19001-2016 quality system certificates, and ISO14001:2015、GB/T24001-2016 Environmental management system certifications.

Our main products are A&B series standard precision roller chains, conveyor chains, special chains with attachments, welded chains, leaf chains, and sprockets. All products are conform to GB、ISO、ANSI、DIN standard with stainless steel SS304, SS310, SS321,SS316, SS410, SS420, SS431, SS630, SS2205 and etc. The products are widely used in food processing, pharmaceutical and chemical industries, electronics, household appliances, automotive manufacturing, machinery, metallurgy, sewage treatment and other industries. Fubang’s products can be customized according to the customers' drawings and samples. Custom Food Machinery Industry Chains. The products have the characteristics of high strength, strong corrosion resistance, strong abrasion resistance, and long service life. The company enjoys a high reputation in the domestic market, and its products are exported to Europe, America, and Southeast Asia.

We are building a new company, Fubang Precision, with products for Biopharmaceutical equipment, heat exchangers, air conditioning, and inspection devices for the oil field.

Fubang adheres to the concept of giving priority to service and the courage to change to meet the needs of customers, and always insists on providing high-quality services for domestic and foreign customers.

Learn about our industry exhibition information and recent events in our company.

-

Combining Stainless Steel Roller Chains: Practical Methods for Stronger, Longer-Lasting Power Transmission

Understanding Why Stainless Steel Roller Chains Are Combined Combining stainless steel roller chains is a common practice in industrial environments w...30 -

Stainless Steel Roller Chains: Comprehensive Guide for Durability and Performance

Introduction to Stainless Steel Roller Chains Stainless steel roller chains are essential components in mechanical power transmission, widely used in ...23 -

Sewage Treatment Chains: Essential Components for Effective Water Treatment

Introduction to Sewage Treatment Chains Sewage treatment chains are critical components in the operation of water treatment facilities, especially in ...16 -

Maximizing Efficiency and Longevity of Conveyor Chains in Industrial Operations

Understanding Conveyor Chains and Their Industrial Importance Conveyor chains are fundamental components in material handling systems across industrie...09

What Food Processing Equipment Is the Food Machinery Industry Chain of Suzhou Fubang Machinery Chain Transmission Manufacturing Co., Ltd. Usually Used For?

In the dynamic and demanding field of food processing, the reliability of equipment components can make or break operational efficiency. At the heart of this intricate ecosystem lies the food machinery industry chain, a vital component for ensuring smooth processes across various stages of production. Among the key players in this domain is Suzhou Fubang Machinery Chain Transmission Manufacturing Co., Ltd. (Fubang), a company renowned for its specialization in stainless steel chains designed to meet the rigorous demands of the food industry.

A Brief Overview of Suzhou Fubang

Established in 2018, Fubang emerged from its predecessor, Suzhou Fulong Stainless Steel Chain Factory, which began operations in 1997. Over two and a half decades, the company has honed its expertise in the design, manufacture, and sale of stainless steel chains. Situated at No.6 Shengtai Road, Xiangcheng District, Suzhou, the company’s 18,000-square-meter facility serves as a hub for innovation and precision.

Fubang’s dedication to quality is evidenced by its collaboration with Jiangnan University in setting up an R&D cooperation center. Recognized as a National High Technology Enterprise and a member of the National Chain Transmission Standardization Technology Committee, Fubang has secured certifications such as ISO9001:2015, GB/T19001-2016, ISO14001:2015, and GB/T24001-2016. These credentials attest to the company’s commitment to excellence in both product quality and environmental stewardship.

Food Machinery Applications

Fubang’s stainless steel chains are engineered to support a diverse array of food processing equipment. Their products are designed to operate seamlessly in challenging environments, offering exceptional resistance to corrosion and wear. Below is a breakdown of the primary equipment categories where Fubang’s chains excel:

1. Food Processing Equipment

Fubang’s chains are integral to machinery used in cutting, mixing, and processing raw ingredients. Their ability to endure rigorous cleaning protocols and resist chemical exposure ensures hygienic and efficient operations.

2. Freezing Systems

Cold chain logistics are a cornerstone of modern food safety. Fubang’s products are designed to withstand extreme temperatures, ensuring durability in freezing tunnels and refrigerated conveyors.

3. Baking Equipment

In high-temperature environments like ovens, Fubang’s chains offer unparalleled thermal resistance. They maintain structural integrity and performance under intense heat, ensuring continuous and efficient baking cycles.

4. Packaging Machinery

Precision and reliability are critical in food packaging. Fubang’s chains provide smooth, uninterrupted performance in packaging lines, whether for bagging, bottling, or wrapping operations.

5. Specialized Machinery

From washing systems to conveyorized cooking units, Fubang’s ability to customize chains for specific applications makes them a preferred choice for manufacturers with unique requirements.

Technical Superiority and Versatility

Fubang’s chains are crafted using a wide range of stainless steel grades, including SS304, SS316, SS321, and SS2205, to address the specific demands of various food machinery applications. These materials are selected for their high tensile strength, corrosion resistance, and extended service life, ensuring minimal downtime and maximum productivity.

Ensuring Hygiene and Safety

In an industry where hygiene and safety standards are non-negotiable, Fubang’s food machinery industry chain stand out for their compliance with food-grade certifications such as FDA and EU regulations. Their advanced surface treatments and meticulous manufacturing processes reduce the risk of contamination and ensure consistent performance under stringent sanitation protocols.

Suzhou Fubang Machinery Chain Transmission Manufacturing Co., Ltd. has cemented its position as a trusted partner for the food industry. By delivering chains that meet the exacting demands of food processing equipment, Fubang empowers manufacturers to achieve efficiency, reliability, and compliance in their operations.

For businesses seeking robust, hygienic, and customizable solutions for their food machinery needs, Fubang’s industry chain offers unparalleled quality and value.

简体中文

简体中文 English

English русский

русский Español

Español